A Shift Towards Robotics in Manufacturing

In New Hampshire, the labor shortage is pushing manufacturers towards automation and robotics at an unprecedented pace. Renowned for its industrial cutting systems, Hypertherm has incorporated automated mechanisms to handle high volumes of small components, allowing human workers to focus on more intricate tasks. In an intriguing development, BJ’s Wholesale Club features a friendly robot, Tally, that navigates store aisles, diligently managing inventory.

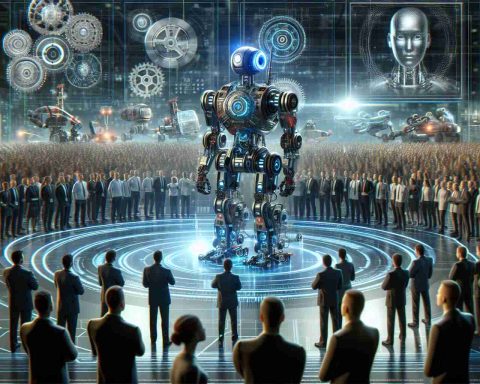

Experts emphasize that we are witnessing the fourth industrial revolution, characterized by rapid advancements unlike previous shifts driven by steam, electricity, and computing. According to a leading figure in manufacturing partnerships, the future job landscape will require workers to engage with technology rather than perform repetitive manual tasks.

To prepare the workforce, educational institutions are customizing training programs to equip individuals with necessary technical skills. Recent reports indicate the need for 4 million manufacturing jobs nationwide by 2030, driven largely by retirements, presenting a significant challenge particularly in New Hampshire, where a large portion of its manufacturing workforce is nearing retirement age.

As automation becomes integral, the benefits are clear: enhanced productivity, improved safety, and consistent quality. While some worry about job loss due to robots, industry experts maintain that these technologies are designed to complement—not replace—human labor. Robotics is revolutionizing tasks deemed unsafe, tedious, or difficult, allowing workers to thrive in more complex roles, ultimately leading to a robust manufacturing landscape in New Hampshire.

Robotics Reshaping the Future of Manufacturing: Opportunities Beyond Automation

A Shift Towards Robotics in Manufacturing

The landscape of manufacturing is undergoing a significant transformation driven by automation and robotics, especially in regions such as New Hampshire, where labor shortages are acute. This evolution is not just about replacing human roles; it’s about enhancing the efficiency and safety of manufacturing processes. Companies like Hypertherm are at the forefront, utilizing robotics for high-volume tasks while human workers focus on complex challenges that require critical thinking and creativity.

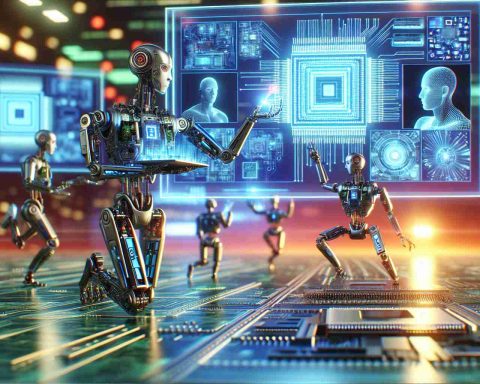

# Understanding the Fourth Industrial Revolution

This current era, termed the fourth industrial revolution, is marked by rapid technological advancements that surpass the transitions triggered by steam power, electricity, and computing. Experts predict that future jobs in manufacturing will necessitate a collaborative relationship with technology, rather than repetitive manual work. This shift requires a workforce adept in various technical skills, prompting educational institutions to develop tailored training programs to fill the anticipated 4 million manufacturing jobs by 2030.

# Advantages of Robotics in Manufacturing

The integration of robotics into manufacturing brings numerous benefits, including:

– Enhanced Productivity: Automation allows for continuous operation, significantly increasing output.

– Improved Safety: Robots can perform hazardous tasks, reducing workplace injuries.

– Consistent Quality: Automated processes can provide precision and uniformity that human labor may not match.

These benefits underscore the potential for a more resilient manufacturing sector.

# Addressing Job Concerns

While the rapid advancement of robotics raises concerns about potential job losses, industry leaders argue that these technologies are intended to complement human labor, not replace it. The role of workers is expected to evolve, focusing on overseeing automated processes, maintenance, and more strategic tasks that require human oversight. Robotics are particularly beneficial in roles that are considered unsafe or monotonous, allowing humans to engage in more intellectually challenging work.

# The Future Workforce: Preparing for Change

To navigate this changing landscape, educational systems must be proactive. Programs that offer training in technical skills, robotics, and digital technologies are essential for preparing the workforce of the future. Collaborations between manufacturers and educational institutions can bridge the skills gap, meeting the rising demand for qualified personnel.

# Potential Limitations and Challenges

Despite the advantages, the transition to automation and robotics is not without challenges:

– Initial Investment Costs: The upfront cost of implementing robotic systems can be significant, posing a barrier for smaller manufacturers.

– Skills Gap: Many existing workers may lack the necessary skills to interact with advanced technologies, necessitating extensive training programs.

– Cultural Resistance: Some employees may resist the change, fearing job displacement or a loss of traditional manufacturing roles.

# Market Insights and Trends

The trend towards automation and robotics in manufacturing is expected to continue growing. The global industrial robotics market is projected to reach $60 billion by 2026, representing a robust opportunity for innovation. The demand for more efficient operations and an enhanced focus on workplace safety will further drive this growth.

# Conclusion: Embracing Robotics for a Sustainable Future

The integration of robotics in manufacturing signifies not just an adaptation to current challenges but a strategic move toward sustainable growth. By embracing this shift, manufacturers can enhance productivity, safety, and quality, thereby laying a solid foundation for the future workforce. As the industry evolves, staying informed and adaptable will be critical for workers and businesses alike.

For more insights on manufacturing trends, visit Manufacturing.net.