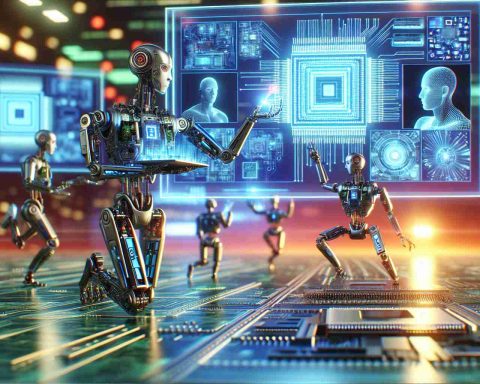

Exciting times are ahead in the world of robotics! After just over two years since its inception, the innovative company Figure has announced that its highly anticipated Figure 02 humanoid robot is now operational with its first commercial clients. This breakthrough comes as CEO Brett Adcock confirmed the robot’s successful deployment via LinkedIn.

Figure 02 stands at 5 feet 6 inches and weighs 155 pounds. Designed for manufacturing and logistics applications, it boasts impressive capabilities including the ability to carry loads of up to 44 pounds, work for five hours on a single charge, and navigate at speeds nearing three miles per hour. One of its remarkable features is its dexterous hands, which allow it to perform tasks like opening doors, climbing stairs, and even handling tools.

In a partnership with BMW, the robot is already contributing to an assembly line by transferring parts, showcasing its potential for multitasking. Remarkably, Figure 02 has been developed to be seven times faster than its predecessor, significantly touching on the speed at which humanoid robotics are evolving.

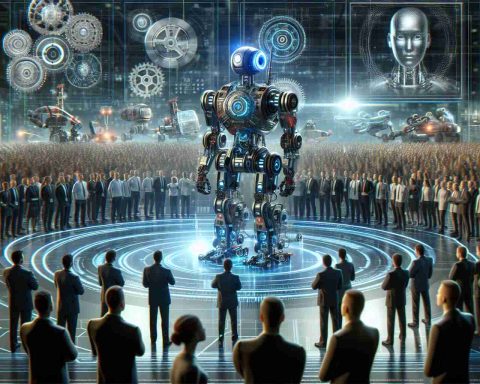

Looking ahead, it is predicted that as advancements continue, the cost of employing these robots could dip below $500 per month, making them a cost-effective solution for a variety of industries. As these robots integrate further into the workforce, we may see a drastic shift in how labor is priced and executed across the globe.

Revolutionizing Industry: The Future of Humanoid Robotics with Figure 02

The current landscape of robotics is poised for transformation, largely due to the recent developments by Figure, a pioneering company in humanoid robotics. With the operational launch of the Figure 02 humanoid robot, significant advancements in manufacturing and logistics are already being witnessed.

Overview of Figure 02

The Figure 02 humanoid robot is an impressive feat of engineering, measuring 5 feet 6 inches tall and weighing 155 pounds. Its design is specifically tailored for industrial applications, rendering it highly effective for tasks such as assembly line operations and material handling. The robot’s capabilities include:

– Load Capacity: It can carry up to 44 pounds, making it suitable for transporting components and tools.

– Operational Duration: With a runtime of five hours on a single charge, it ensures efficiency in productivity.

– Mobility: Capable of navigating at speeds approaching three miles per hour, it can adeptly maneuver through diverse environments.

Key Features

One of Figure 02’s standout features is its highly dexterous hands, which enable it to perform complex tasks, such as:

– Opening doors

– Climbing stairs

– Handling tools with precision

These capabilities enhance its versatility across various sectors, particularly in manufacturing and logistics environments where efficiency is paramount.

Collaborations and Practical Applications

Figure has aligned itself with industry giants like BMW, showcasing the robot’s strengths in real-world applications. Currently, Figure 02 is an integral part of BMW’s assembly line, where it is responsible for transferring parts. This collaboration not only highlights the robot’s functionality but also sets a precedent for future implementations of humanoid robots in manufacturing settings.

Trends and Market Predictions

As the technology evolves, experts predict a dramatic shift in the cost dynamics of employing humanoid robots. It is anticipated that the monthly operational cost for businesses could drop below $500, significantly democratizing access to advanced robotic solutions. This shift is expected to alter labor market structures, potentially leading to more automated processes in previously labor-intensive sectors.

Pros and Cons of Humanoid Robotics

Pros:

– Increased Efficiency: Robots can work continuously without fatigue, increasing overall productivity.

– Versatility: The ability to perform a variety of tasks makes humanoid robots adaptable to different roles within industries.

– Cost Reduction: As prices decrease, businesses can realize substantial savings in labor costs.

Cons:

– Initial Investment: High initial costs for deployment and integration into existing systems can be a barrier.

– Job Displacement: The rise of robots may lead to concerns regarding workforce displacement in certain sectors.

– Maintenance Needs: Regular upkeep and potential technical issues may require dedicated support staff.

Conclusion

The trajectory of Figure 02 and its deployment in commercial settings paints a bright future for humanoid robotics in industry. As advancements continue and costs decrease, the integration of such technology into the workforce may redefine productivity and labor economics worldwide. For more insights on robotics and technology trends, visit Figure.