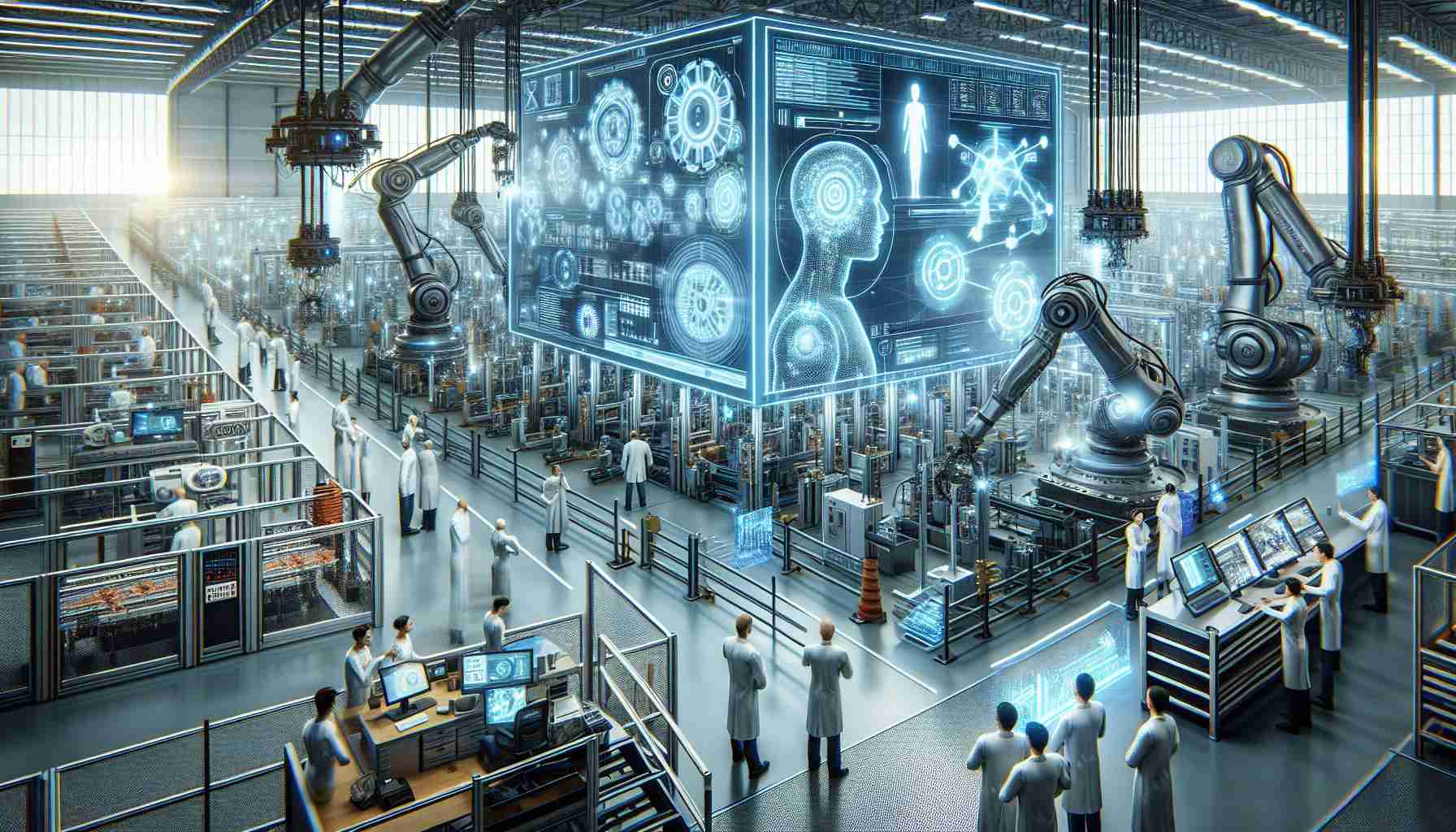

The future of manufacturing is unfolding at YOKE Industrial Corp., where innovation thrives at the intersection of robotics and skilled labor. In Taiwan, their 56m² smart factory exemplifies how advanced technology and human expertise can join forces to enhance efficiency and sustainability in producing industrial lifting equipment.

YOKE’s proactive approach includes an employee-driven suggestion program launched in 2021, encouraging workers to submit innovative ideas monthly. The best suggestions are rewarded, fostering a culture where every voice plays a role in shaping operational excellence. The company views this initiative as essential in marrying advanced technology with human creativity, propelling both YOKE and the manufacturing sector forward.

Since 2011, YOKE has significantly invested in automation, now operating 71 systems and over 108 robotic arms, including industry-leading products from Fanuc. Their $30 million investment translates into an impressive output of 20 million units annually, showcasing automation as an enhancer of human capability rather than a replacement.

The smart factory is a dynamic entity, evolving with new automation technologies like Automated Guided Vehicles and real-time digital data platforms. This innovative environment supports employees in transitioning from manual tasks to roles that emphasize problem-solving and technical skills, making it an attractive place for the younger workforce drawn to tech-centric careers.

YOKE’s forward-thinking integration of automation and digitalization is not just about productivity; it is a holistic strategy aimed at sustaining their competitive edge in a fast-evolving industry. Partnering with Fanuc has been crucial, equipping YOKE with state-of-the-art tools to maintain high-quality standards and innovation in manufacturing.

The Future of Manufacturing: How YOKE Industrial Corp. is Pioneering Innovations

The Intersection of Robotics and Skilled Labor

YOKE Industrial Corp. is leading the charge in transforming the manufacturing landscape, where the integration of robotics and skilled human labor creates a new paradigm for efficiency and sustainability in producing industrial lifting equipment. Their smart factory, covering an area of 56m² in Taiwan, serves as a model for what the future of manufacturing can look like in an increasingly technology-driven world.

Employee Empowerment through Innovation

In a remarkable initiative launched in 2021, YOKE implemented an employee-driven suggestion program that invites workers to contribute innovative ideas on a monthly basis. This program not only rewards the best suggestions but also cultivates a culture of collaboration and continuous improvement. By valuing each employee’s input, YOKE is merging technological advancement with human creativity, illustrating the essential role of the workforce in achieving operational excellence.

Heavy Investment in Automation

Since 2011, YOKE has dedicated substantial resources to automation, resulting in the implementation of 71 automated systems and over 108 robotic arms, notably featuring advanced products from Fanuc. This $30 million investment has propelled their production capabilities, enabling the company to manufacture an impressive 20 million units annually. This strategic move emphasizes the philosophy that automation enhances human capability rather than replacing it, paving the way for a more skilled workforce.

The Dynamic Smart Factory Environment

YOKE’s smart factory is intensely adaptive, continuously evolving with cutting-edge automation technologies, such as Automated Guided Vehicles (AGVs) and real-time digital data platforms. This progressive environment not only streamlines manufacturing processes but also encourages employees to transition from traditional manual tasks to roles that require advanced problem-solving and technical skills. Such an approach is particularly appealing to the younger workforce, who are increasingly attracted to tech-centric careers.

Strategic Partnerships for Quality and Innovation

To maintain its competitive edge, YOKE has partnered with Fanuc, leveraging state-of-the-art robotics and automation tools to uphold high-quality manufacturing standards. This collaboration is a cornerstone of their holistic strategy, which marries digitalization with productivity enhancements. The focus on sustainable practices, efficiency, and innovative methodologies ensures that YOKE remains a significant player in a rapidly changing industry landscape.

Insights and Trends

– Market Analysis: As manufacturing continues to evolve, companies that adopt smart factory technologies like YOKE are likely to see enhanced productivity and employee satisfaction.

– Sustainability: YOKE’s initiatives illustrate the growing trend of sustainability in manufacturing, highlighting the importance of efficient resource use and waste reduction.

– Future Predictions: As automation continues to advance, more manufacturers will integrate employee-driven innovation programs to capitalize on combined human-robot strengths.

Conclusion

YOKE Industrial Corp. is not just reshaping its own manufacturing processes but is also contributing to a broader transformation in the industry. Through significant investments in automation, a commitment to employee engagement, and strategic partnerships, YOKE exemplifies how modern manufacturing can harness the power of technology and human creativity to achieve excellence. As the sector moves forward, YOKE stands as a beacon of innovation and sustainable practices that can inspire other companies to follow suit.

For more information on manufacturing innovations and industry trends, visit YOKE Industrial Corp..