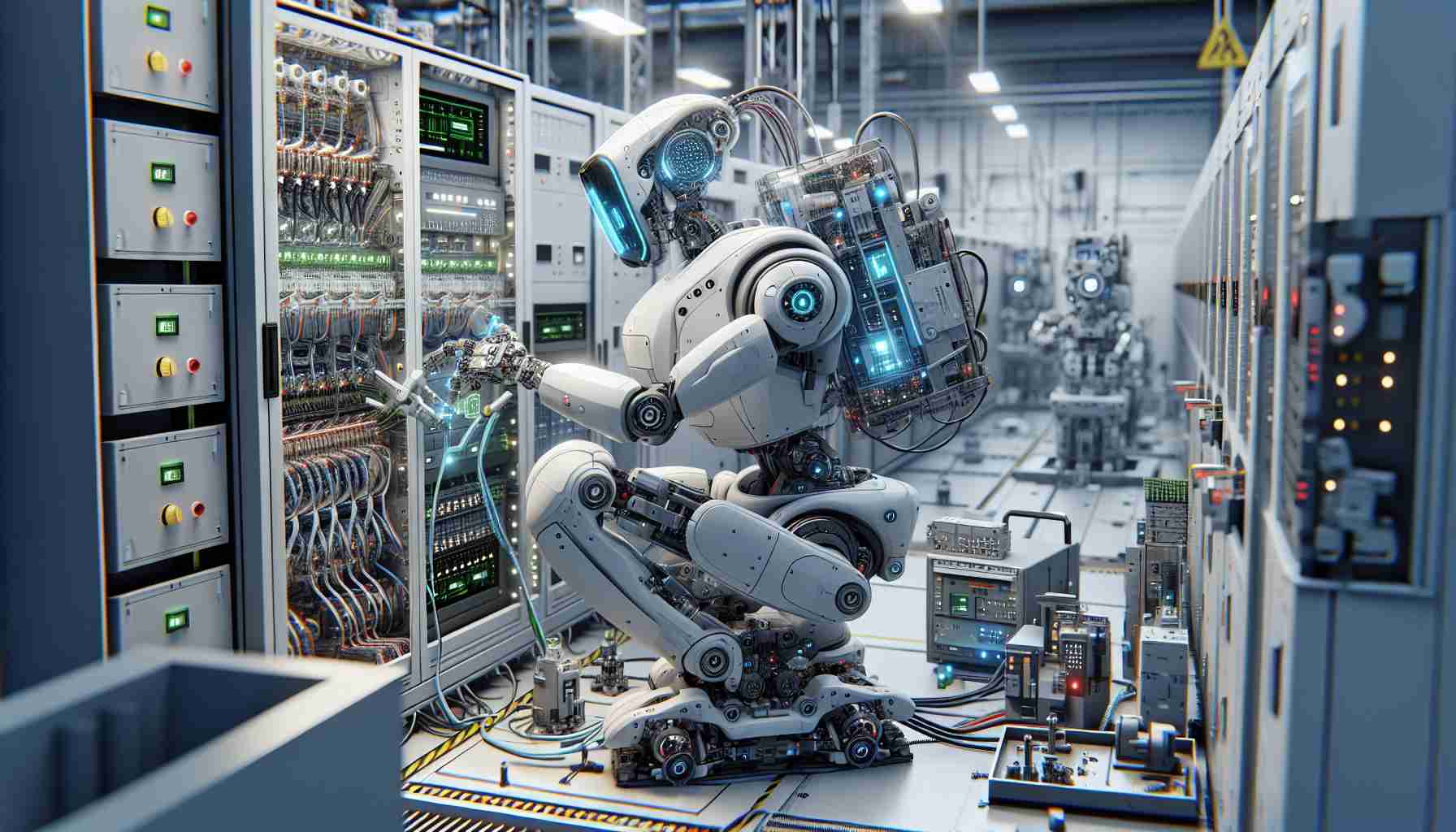

In a groundbreaking move to enhance electricity reliability, Consumers Energy has introduced an innovative ally to assist in the upkeep of vital infrastructure. Meet Spot, a cutting-edge robot dog that patrols the Blackstone Substation in Jackson. This high-tech machine is equipped with advanced sensors and thermal imaging technology that allow it to detect potential issues in electrical connections before they escalate into more significant problems.

Spot operates autonomously, conducting routine inspections across the facility. By gathering critical data about the electrical systems, it relays this information back to headquarters, essentially acting as an early warning system. If the robot identifies a “hotspot”—a sign of potential electrical failure—maintenance crews are alerted for immediate action.

According to its handlers, Spot is not just a novelty; it represents a serious commitment to technological enhancement in maintenance processes. With a price tag of over $200,000, this state-of-the-art robot underscores the company’s vision for a modernization strategy that leverages robotics alongside traditional human efforts.

As the energy landscape continues to evolve, corporate leaders at Consumers Energy are exploring the integration of more robotics and advanced technologies, including drones. The introduction of Spot marks just the beginning of a broader initiative aimed at ensuring efficient power delivery and minimizing outages for the community.

Meet the Robot Changing How We Maintain Our Power Supply!

In an age where technological advancements are reshaping industries, the introduction of robots in utilities maintenance signifies a major leap forward. Spot, the robotic dog deployed by Consumers Energy, is just the tip of the iceberg in revolutionizing how electricity supply systems are monitored and managed. This innovative approach not only enhances safety and efficiency but also offers a glimpse into the future of utility maintenance.

Key Questions About Spot and Its Impact

1. What specific tasks can Spot perform that traditional methods cannot?

Spot’s advanced sensors and thermal imaging capabilities enable it to detect minute changes in temperature and structural integrity that human inspectors might miss, thereby acting as a diagnostics tool in real-time.

2. How does the use of Spot affect job security for maintenance workers?

While there is concern that automation could threaten jobs, the reality is that Spot is designed to assist human workers, allowing them to focus on more complex tasks. The robot’s data helps technicians prioritize their work, potentially leading to new job opportunities in robot maintenance and data analysis.

3. What are the long-term plans for robotics in utility maintenance?

Consumers Energy is planning to expand its robotics program, potentially integrating drones for aerial inspections and other robotic systems for various maintenance tasks, further automating the process while still relying on human oversight.

Challenges and Controversies

Despite the exciting prospects, using robots like Spot comes with challenges.

– Technical Limitations: While Spot gathers valuable data, it may still face difficulties in extremely complex environments or during adverse weather conditions.

– Cost Concerns: The investment in high-priced robots can lead to debates over financial prioritization within utility companies, especially in regions where infrastructure is aging and requires immediate upgrading.

– Data Privacy & Security: As robots gather and transmit data, concerns over handling sensitive information and cybersecurity risks have arisen.

Advantages of Integrating Robotics

1. Increased Efficiency: Spot operates around the clock, significantly decreasing the time required for regular inspections and potentially reducing outages.

2. Enhanced Safety: Deploying robots to dangerous infrastructure reduces human exposure to high-risk environments, minimizing on-site accidents.

3. Predictive Maintenance: The real-time data Spot provides allows for predictive maintenance scheduling, which can save companies money by preventing costly failures before they occur.

Disadvantages of Robot Integration

1. High Initial Investment: The cost of advanced robotic systems can be prohibitive, particularly for smaller utility providers.

2. Dependence on Technology: Relying heavily on robots could be risky if failures occur or if maintenance personnel lack the necessary training to operate emergency scenarios without robotic assistance.

3. Job Displacement Concerns: Even if robots create new opportunities, they may also lead to potential job losses in areas traditionally managed by human workers.

As we continue to rely more on technology to maintain vital services, the emergence of robots like Spot showcases how innovation can align with operational needs and safety concerns. In the long run, balancing technological adoption with workforce considerations will be essential in shaping the future of energy maintenance.

For more information on how technology is transforming utilities management, visit Consumers Energy.