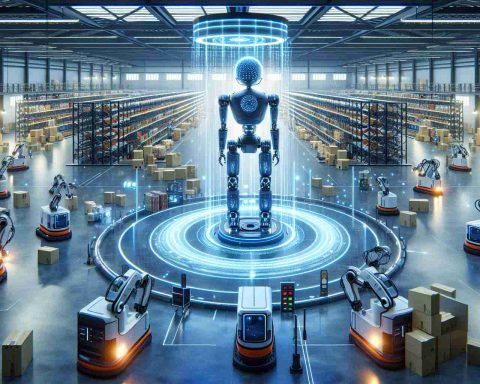

In a cutting-edge demonstration at Robust AI’s headquarters, the Carter Pro robot showcased its remarkable abilities in a controlled warehouse environment. One striking feature of the setting is the modular shelving units designed for optimal visibility and access, enhancing the overall workflow.

The standout aspect, however, isn’t solely the robot’s impressive design; it’s the interaction between Carter and the human workers. Employees engage with the robot directly, often picking it up and repositioning it as necessary. This hands-on relationship emphasizes a collaborative approach within the workplace, a significant shift from traditional automated systems.

As the demand for safer work environments rises, understanding how humans can effectively work alongside robots is crucial. For Carter, the ability to adapt in response to human interaction ensures a blend of independence and responsiveness. The robot features a unique orange handle that allows for easy maneuvering, a notable achievement in robotics design.

Furthermore, Robust AI’s CTO, previously of Rethink Robotics, champions the idea of harmonious human-robot coexistence. Instead of following trends dictated by large corporations, Robust AI aims to diversify its client base, ensuring long-term stability and success.

With early tests underway with major logistics partners like DHL, Carter’s innovative approach positions it as a significant player in the future of automated warehouse operations. The integration of cameras over lidar technology signifies a tactical shift, prioritizing cost-effectiveness and functionality in real-world applications.

Revolutionizing Warehouse Efficiency: Meet the Robot That Could Change Everything!

The landscape of warehouse operations is on the brink of a dramatic transformation, primarily driven by advancements in robotics. The latest innovation, the Carter Pro robot by Robust AI, is not just a marvel of engineering but a symbol of how technology can reshape the way we think about labor and productivity in warehouses.

What specific capabilities does the Carter Pro robot possess?

Beyond its ability to facilitate material movement with ease, the Carter Pro robot is equipped with advanced machine learning algorithms that enable it to continually adapt and improve its operational efficiency over time. It can learn from its environment and interactions, optimizing its performance in response to changing warehouse layouts and workflows.

How does the Carter Pro address safety concerns in the workplace?

The robot is designed with a variety of safety features including real-time obstacle detection and emergency stop mechanisms. By allowing for safe interaction with human workers, it significantly reduces the risk of accidents in environments where heavy machinery is often present, making it an attractive asset for companies prioritizing employee safety.

What are the key challenges associated with integrating robots like Carter Pro in warehouses?

One major challenge includes the cost of implementation. While robots can potentially reduce long-term operational expenses, the initial investment can be a barrier for many businesses, especially smaller enterprises. Additionally, there is the challenge of workforce adaptation; employees may need training to work alongside robots effectively, which can lead to resistance or unease about job security.

Are there any controversies surrounding the adoption of robotics in warehouses?

Yes, the rise of robotics in warehouses has sparked debates regarding job displacement. Many workers fear that the increasing efficiency of robots could lead to significant job losses. Conversely, proponents argue that robots can take over mundane tasks, allowing human workers to focus on higher-value activities.

What are the advantages of the Carter Pro robot?

The advantages of adopting the Carter Pro robot include:

1. Improved Efficiency: With its ability to operate continuously without breaks, the robot can significantly enhance productivity levels within a warehouse.

2. Adaptability: The robot’s machine learning capabilities mean it can evolve with the workspace, adjusting to new tasks and layouts with minimal downtime.

3. Enhanced Safety: By working alongside humans and managing hazardous materials, the robot can create a safer work environment.

What are the disadvantages?

However, there are also disadvantages to consider:

1. High Initial Costs: The upfront investment in robotics technology can be substantial.

2. Maintenance and Downtime: Robots require maintenance, and any downtime due to repairs can affect overall productivity.

3. Technological Dependence: Increased reliance on technology can pose risks if systems fail or require upgrades, leading to possible disruptions in operations.

As the integration of robots like Carter Pro continues to evolve, the implications for the future of warehouse operations remain profound. Companies must navigate these advancements with a keen understanding of their unique challenges and benefits to ensure they harness the full potential of robotics while maintaining a balanced workforce.

For more insights into the future of warehouse technology, visit Robust AI.