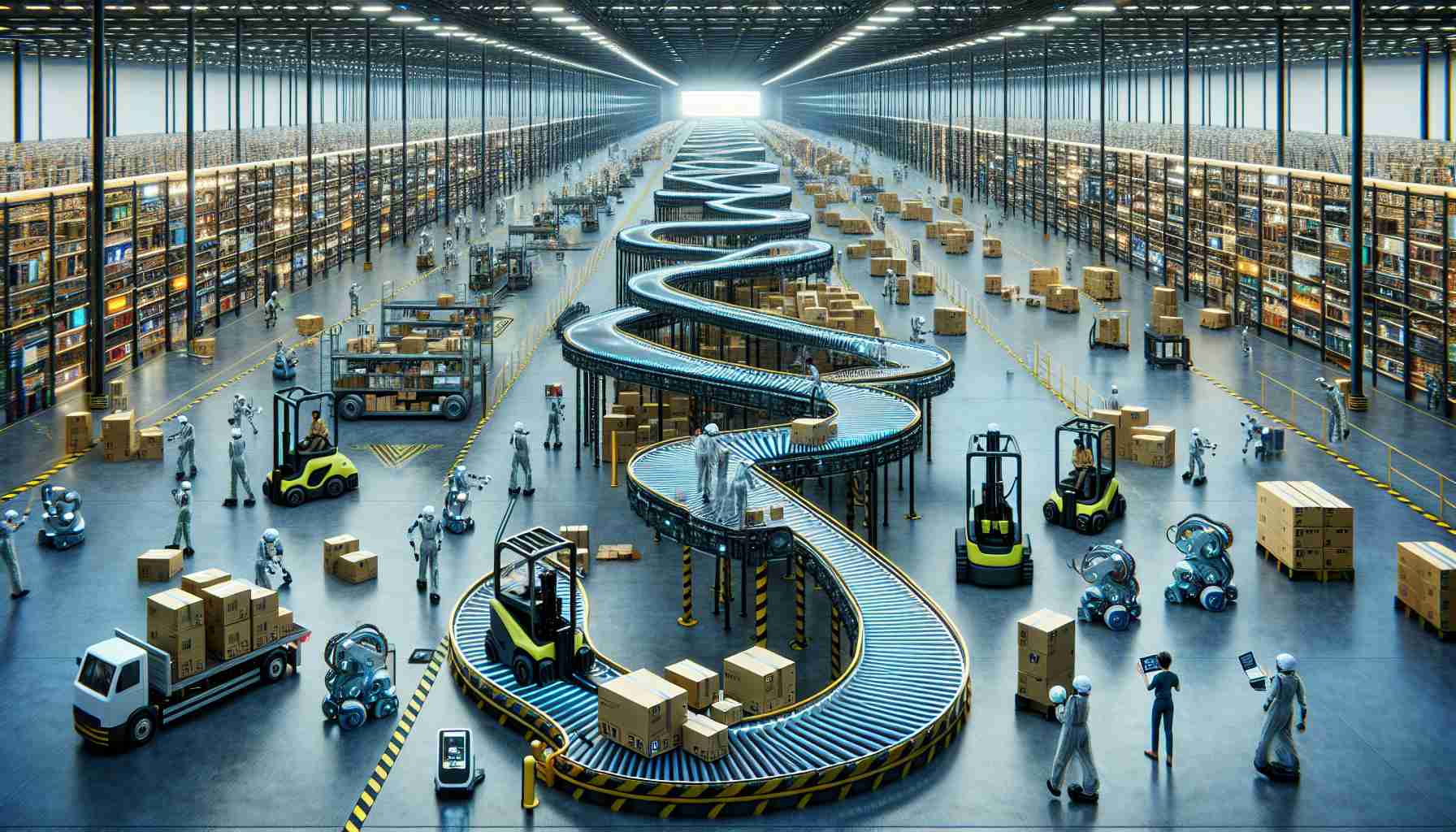

The Emergence of Warehouse Robotics

The landscape of warehouse management is rapidly evolving with the integration of automated systems like autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and robotic arms. These technologies are designed to enhance efficiency in managing tasks such as picking, sorting, and packing.

By 2031, the warehouse robotics market is expected to reach a staggering valuation of £27.9 billion, reflecting a remarkable compound annual growth rate (CAGR) of 27.9% from 2022. This significant growth is largely attributed to several key factors driving the demand for automation in warehouses.

The rise of e-commerce has created a pressing need for swift and accurate order fulfilment. In addition, many businesses face labour shortages, prompting the adoption of robotic solutions as substitutes for human workers, especially during peak times. Furthermore, advancements in technology, such as artificial intelligence and machine learning, offer smarter, more efficient operational capabilities.

However, challenges persist. High initial investment costs pose a barrier for many companies, as does the complexity of integrating new robotics with existing systems. Moreover, there are concerns surrounding cybersecurity due to the interconnected nature of these technologies.

As industries move toward more intelligent warehouses, the future looks bright for integrated robotic systems, positioning them as essential components for maintaining competitive advantage.

Transforming Warehousing: The Future of Robotics and Automation

The Emergence of Warehouse Robotics

The landscape of warehouse management is undergoing a radical transformation with the integration of advanced robotic technologies. Autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and robotic arms are increasingly adopted to streamline operations such as picking, sorting, and packing.

# Market Growth and Predictions

By 2031, the warehouse robotics market is projected to achieve a remarkable valuation of £27.9 billion, reflecting a compound annual growth rate (CAGR) of 27.9% from 2022. This impressive growth trajectory is largely driven by the surging demand for rapid and efficient order fulfilment, fuelled in part by the booming e-commerce sector.

Key trends contributing to this growth include:

– Increased E-commerce Demand: With online shopping on the rise, warehouses must adapt to ensure fast and accurate order processing.

– Labour Shortages: Many businesses are struggling to find adequate staffing, leading to a greater reliance on robotic systems to fill gaps during peak periods.

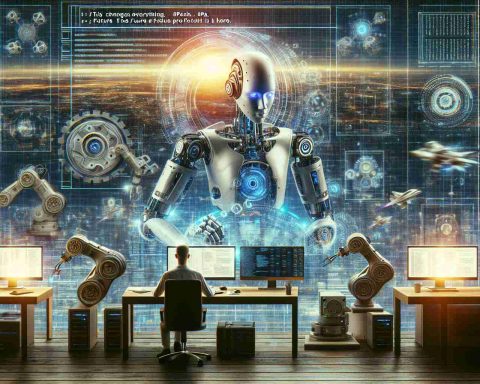

– Technological Advancements: Innovations in artificial intelligence (AI) and machine learning are enabling more sophisticated automation solutions.

# Pros and Cons of Warehouse Robotics

Pros:

– Enhanced operational efficiency and speed.

– Reduced labour costs in the long run.

– Improved accuracy in order fulfilment.

– Scalability to meet fluctuating demand.

Cons:

– High initial capital investment required for implementation.

– Integration challenges with existing systems.

– Potential cybersecurity vulnerabilities due to increased connectivity.

# Use Cases of Warehouse Robotics

Warehouse robotics are utilised in various scenarios, including:

– Order Picking: Robotic systems excel in accurately and quickly picking items from shelves, which is essential during high-demand seasons.

– Inventory Management: Robots can assist in real-time inventory tracking, reducing the risk of stock discrepancies.

– Packing and Shipping: Automated packing arms can optimise packing processes, ensuring efficient use of space and materials.

# Limitations and Challenges

Despite their many advantages, several limitations affect the widespread adoption of robotics in warehouses:

– Integration Complexity: Companies face difficulties when attempting to integrate new robotic technologies with legacy systems, which can stall productivity.

– Initial Costs: The costs associated with purchasing and installing robotic systems can be prohibitive, particularly for small and medium-sized enterprises.

– Cybersecurity Issues: As robotic systems become increasingly interconnected, the risk of cyber threats necessitates robust security measures.

# Current Trends and Innovations

The warehouse robotics sector is witnessing several notable trends, including:

– Collaborative Robots (Cobots): These robots are designed to work alongside human workers, enhancing productivity without replacing jobs.

– Data Utilisation: Advanced data analytics is being leveraged to streamline operations and predict inventory needs.

– Sustainability Efforts: Companies are exploring eco-friendly automation solutions to minimise waste and energy use.

# Future Insights

As industries continue to embrace automation, the role of warehouse robotics is expected to expand. Innovations in technology will likely lead to more efficient and adaptable systems, ultimately reshaping the logistics and supply chain landscape. The importance of cybersecurity measures will also grow, as protecting sensitive data will be crucial in the era of interconnected robotics.

In conclusion, the evolution of warehouse robotics not only presents significant opportunities for operational improvement but also introduces challenges that businesses must address to fully realise the benefits of automation.

For more information about the evolving world of warehouse robotics, visit example.com.