Maxon’s High Efficiency Joint Drive Unveiled

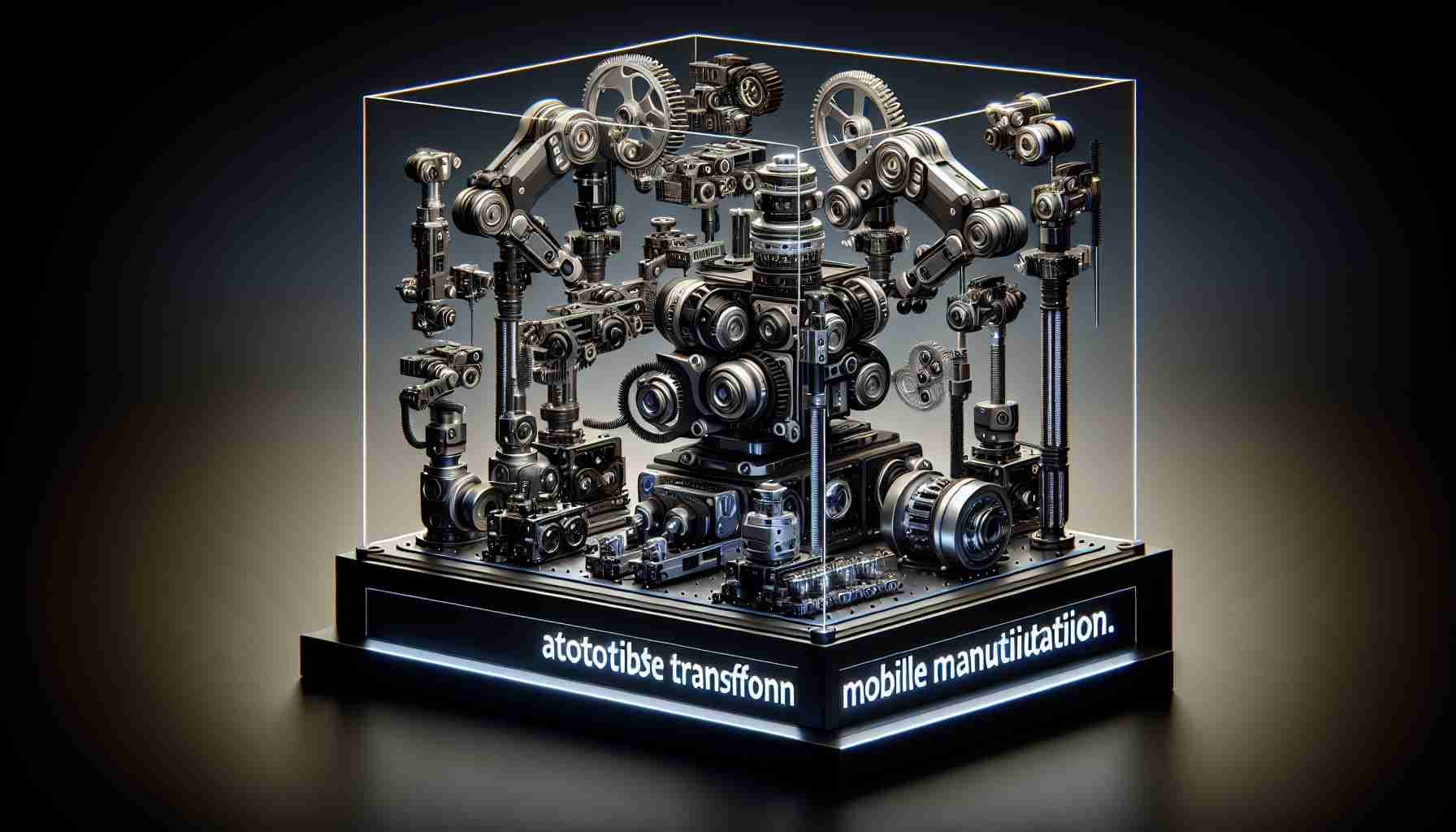

Maxon has introduced an innovative component to its robotic joint lineup: the High Efficiency Joint (HEJ) Drive 70-48-50. This state-of-the-art actuator is engineered to elevate the performance of autonomous mobile robots in unpredictable environments, such as those used in humanoid robots, quadrupeds, exoskeletons, and mobile manipulators.

Weighing just over 1 kg, the HEJ 70-48-50 offers impressive specifications, delivering a peak torque of 50 Nm and achieving speeds of up to 28 rad/s. This blend of compact design and high torque density makes it an outstanding option for tasks requiring mobile manipulation.

Stefan Müller, the Chief Technology Officer at Maxon, emphasized the significant advancements made with this actuator, highlighting its superior efficiency and integration capabilities. The actuator combines several components—torque-dense motors, planetary gears, and advanced electronics—into a single compact package, all while maintaining an IP67 rating for dust and water resistance.

The HEJ 70-48-50 is designed for quick deployment in robotic applications, enabling innovative engineering solutions through its flexibility and high-efficiency features. Scheduled for release in early Q2 2025, those interested in leveraging this technology can visit Maxon’s website for further details and datasheets.

For additional inquiries, you can reach out directly via their contact information.

Revolutionizing Robotics: Maxon’s New High Efficiency Joint Drive

Maxon, a leader in high-precision drive systems, has made a significant advancement in robotic technology with the introduction of its High Efficiency Joint (HEJ) Drive 70-48-50. This innovative actuator is designed to enhance the operational capabilities of various autonomous mobile robots, making it well-suited for challenging and dynamic environments.

Specifications and Features

The HEJ Drive 70-48-50 stands out due to its compact design and robust performance metrics, including:

– Weight: Just over 1 kg

– Peak Torque: 50 Nm

– Speed: Up to 28 rad/s

– Ingress Protection Rating: IP67, ensuring durability against dust and water

This unique combination of features allows the HEJ Drive to excel in diverse applications, such as humanoid robots, quadruped systems, exoskeletons, and mobile manipulators, where precision and adaptability are crucial.

Advantages of the HEJ Drive

1. High Efficiency: The design optimizes energy usage, promoting longer operational times for robots.

2. Quick Deployment: Engineers can rapidly integrate the HEJ Drive into new designs, speeding up development cycles.

3. Modular Integration: The actuator incorporates torque-dense motors, planetary gears, and sophisticated electronics within a single unit, minimizing complexity and space usage in robotic designs.

Use Cases

The HEJ Drive 70-48-50 is particularly beneficial in sectors that demand mobility and dexterity, including:

– Industrial Automation: Enhancing robotic arms to perform intricate tasks with precision.

– Healthcare Robotics: Empowering assistive devices and exoskeletons that improve patient mobility.

– Search and Rescue Operations: Assisting robots in navigating unpredictable terrains effectively.

Future Trends and Insights

As robotics technology continues to evolve, the demand for efficient and adaptable actuators like the HEJ Drive will only increase. Industry experts predict a growing trend towards intelligent robotic systems that require less energy while delivering higher performance. The HEJ Drive sets a precedent for future innovations in robotic actuators.

Pricing and Availability

The HEJ 70-48-50 is scheduled for commercial release in early Q2 2025. Interested buyers and developers can find more information, including detailed datasheets, on Maxon’s website [Maxon](https://www.maxonmotor.com).

Conclusion

Maxon’s High Efficiency Joint Drive 70-48-50 marks a significant leap in robotic actuator technology. With its impressive specifications and versatile applications, it is set to transform how robots operate in various industries, paving the way for enhanced efficiency and innovation in the field. For those looking to stay ahead in robotics, this integration of design and performance is a noteworthy advancement.