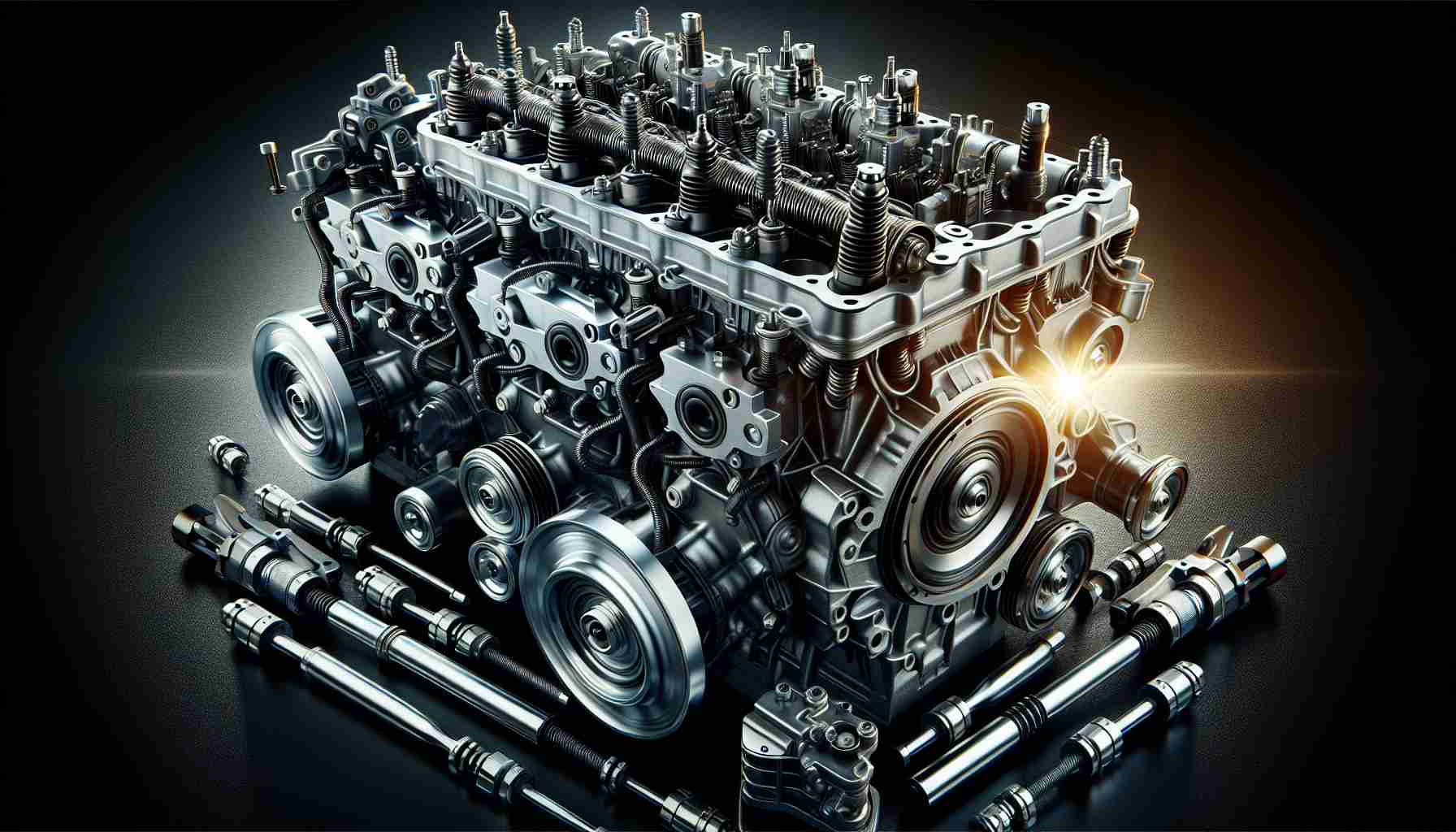

Volkswagen stands out in the automotive industry for producing a diverse range of robust and dependable engines, catering to various driving needs. From the thrilling experience of a Golf R to the practical commuting capabilities of a Tiguan, their vehicles appeal to all types of drivers. Among car enthusiasts, Volkswagen’s engineering is celebrated for delivering some of the most formidable engines globally, with a prominent focus on diesel technology, particularly in Europe where the company thrives.

With a portfolio exceeding ten subsidiaries, Volkswagen’s influence extends across multiple automotive brands, such as Audi, Porsche, and Lamborghini. This interconnectedness means that innovative engines designed by one subsidiary often find their way into vehicles produced by another. Volkswagen’s extensive lineup includes both high-performance engines and efficient diesel options, strengthening its commitment to excellence in automotive engineering.

A notable example is Audi’s 4.0L V8 TDI engine, which was launched in 2003. This advanced V8 engine technically offers a displacement of 3.9 liters and marked a significant milestone as one of the most powerful diesel engines of its time. Producing 275 brake horsepower and an impressive torque of 479 lb-ft, it was exclusively utilized in the Audi D3 A8 model. Although it had a brief production run, the innovations embedded within it paved the way for subsequent models, ensuring this engine’s legacy within the automotive sphere.

Volkswagen’s Engineering Excellence: Innovations in Powerful Engines

Volkswagen has long been synonymous with engineering excellence and innovation in the automotive industry, particularly when it comes to developing powerful engines. While much has been said about its diesel technology and high-performance vehicles, there are additional facets of Volkswagen’s engine engineering that deserve attention.

What distinguishes Volkswagen’s engineering from competitors?

Volkswagen is one of the pioneers in turbocharging technology. Turbocharged engines are designed to offer improved fuel efficiency without sacrificing power. This technology enables smaller engines to produce output comparable to larger, traditionally aspirated engines. For instance, the 1.4L TSI engine, which boasts both turbocharging and supercharging, has redefined performance standards in subcompact vehicles. This not only enhances driving enjoyment but also aligns with modern environmental standards by reducing emissions.

How does Volkswagen ensure the quality and reliability of its engines?

One of the key factors in Volkswagen’s engineering success is its rigorous testing and quality control processes. Engines undergo extensive testing in various environments, simulating real-world conditions to ensure durability and reliability. The company’s investment in advanced manufacturing technologies, like robotics and 3D printing, further enhances precision in engine production.

What are some of the notable challenges faced by Volkswagen?

The infamous diesel emissions scandal, often referred to as “Dieselgate,” raised significant questions around ethics in engineering practices. It highlighted a major challenge in balancing performance goals with regulatory compliance. This controversy not only affected VW’s reputation but also led to a complete re-evaluation of their diesel strategy, prompting a significant pivot towards electric vehicle (EV) technology.

Advantages and Disadvantages of Volkswagen’s Engine Engineering

Advantages:

1. Versatility: Volkswagen produces a wide array of engines that cater to different market segments, from high-performance sports cars to efficient compact vehicles.

2. Innovation: The company is at the forefront of technological advancements, including hybrid and electric powertrains, which are crucial for future sustainability.

3. Global Influence: With subsidiaries like Audi and Porsche, innovative technologies and engineering solutions are shared across brands, enhancing overall performance and appeal.

Disadvantages:

1. Controversy: The legacy of the emissions scandal still looms over the brand, affecting consumer trust and prompting skepticism about future products.

2. Investment Requirements: Transitioning to electric and hybrid technologies involves huge investments, which may strain resources and affect short-term profitability.

3. Market Competition: As the automotive industry rapidly evolves, especially in the EV sector, Volkswagen faces fierce competition from both established manufacturers and new entrants focused on sustainable mobility.

Future Directions in Engine Technology

Volkswagen is making strides in battery technology and electric powertrains. Their MEB (Modular Electric Drive Matrix) platform is designed to standardize electric vehicle production, potentially leading to efficiencies in both manufacturing and performance. This represents a holistic shift in Volkswagen’s engineering philosophy, reflecting a commitment to innovation while addressing the growing demand for environmentally friendly vehicles.

For more insights into Volkswagen’s automotive innovations and engineering prowess, visit Volkswagen’s official website.