Côte d’Ivoire Internet Transformation: Fiber, 5G Ambitions & Satellite Expansion

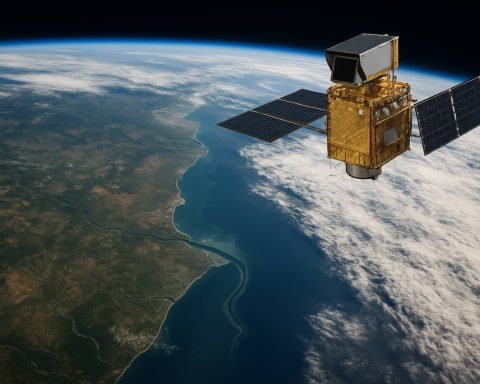

Unleashing Côte d’Ivoire’s Digital Future: Fiber Optics, 5G Aspirations, and Satellite Connectivity Current State of Côte d’Ivoire’s Internet Market Emerging Technologies: Fiber Optics, 5G,