- Dassault Systèmes partners with KUKA’s mosaixx ecosystem, enhancing industrial automation innovation.

- The collaboration merges virtual and physical realms, enabling companies to test and simulate before production.

- Businesses leverage Dassault’s 3DEXPERIENCE platform integrated with KUKA’s robotics for increased efficiency and adaptability.

- Access to powerful software like CATIA and SOLIDWORKS enhances innovation through cloud-based solutions.

- Over four million industrial robots globally could see increased installations, projected to reach 718,000 by 2026.

- This partnership is pivotal for industries aiming to remain competitive in a technology-driven future.

As digital landscapes expand, two giants are causing seismic shifts in the world of industrial automation. Dassault Systèmes catapults into KUKA’s industrious mosaixx ecosystem, promising transformative strides for industry innovators.

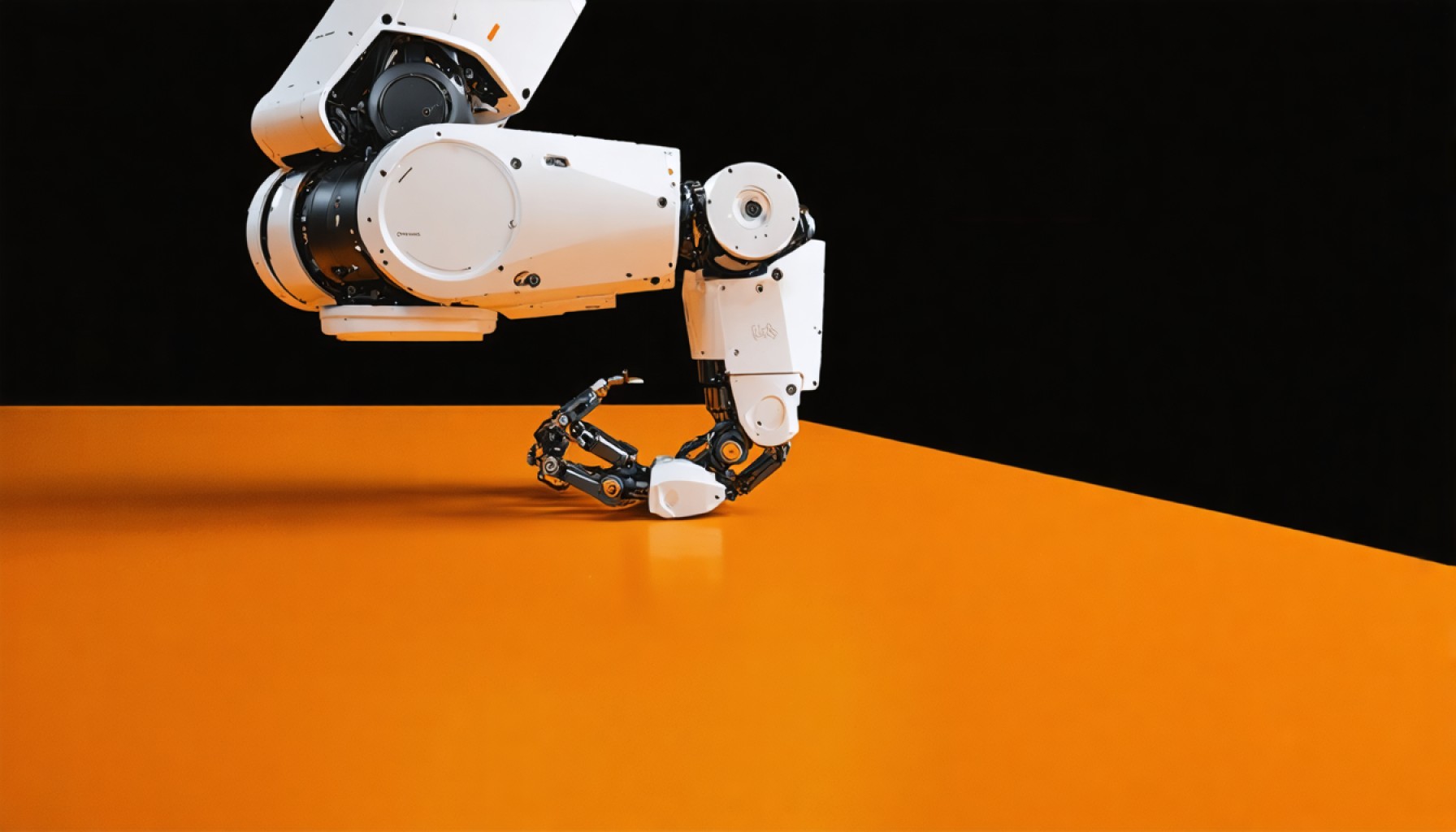

Picture this: a bustling factory floor, suffused with the hum of machines that seem less mechanical and more intuitive, wielding the delicate dance of data and design. Thanks to this collaboration, companies from automotive to healthcare will wield the powerful tools of the 3DEXPERIENCE platform, seamlessly intertwined with KUKA’s robotics expertise.

A world where the physical and virtual realms merge offers companies the ability to test, simulate, and perfect before a single product hits the production line. The result? A future brimming with efficiency and adaptability. This alliance not only widens access to Dassault Systèmes’ renowned software like CATIA and SOLIDWORKS but amplifies the scope for innovation through flexible, cloud-based solutions.

With over four million industrial robots tirelessly working around the globe, the ripple effects of this partnership are vast and promising. Projections suggest a burgeoning rise in installations, with numbers soaring to an impressive 718,000 by 2026.

The fusion of KUKA’s dynamic platform with Dassault’s state-of-the-art applications signals a clarion call for industries seeking to thrive in an era defined by technology and innovation. As the march towards digitalization accelerates, embracing such groundbreaking partnerships becomes not just beneficial, but essential.

This union heralds a new skin for the old ceremony of production, crafting a landscape where digital dreams morph into tangible realities.

How Dassault Systèmes and KUKA are Reshaping Industrial Automation

Introduction to the Partnership

The collaboration between Dassault Systèmes and KUKA is poised to revolutionize the field of industrial automation. It leverages Dassault’s powerful 3DEXPERIENCE platform alongside KUKA’s robotics expertise to create a seamless integration of virtual and physical manufacturing processes. This synergy enables industries to transform their operations for greater efficiency and adaptability.

Real-World Use Cases

1. Automotive Manufacturing: The automotive industry can utilize this integration to enhance precision in assembly lines, reduce time-to-market, and increase vehicle customization options.

2. Healthcare Equipment Production: By using simulation and virtual testing, healthcare equipment can be optimized for performance and safety before manufacturing begins.

3. Consumer Electronics: The collaboration allows for rapid prototyping and validation of designs, reducing the risk of costly errors during mass production.

How-To Steps & Life Hacks

To maximize the benefits of the Dassault Systèmes and KUKA partnership:

1. Integrate Virtual Twin Technology: Use digital twins to create a virtual representation of a product and its manufacturing process for better decision-making.

2. Leverage Cloud-Based Solutions: Implement cloud solutions for scalability and flexibility in design and production workflows.

3. Adopt Adaptive Manufacturing: Customize production lines quickly and efficiently to meet the changing demands of consumers.

Market Forecasts & Industry Trends

The industrial robotics market is on a steady growth trajectory. According to industry projections, installations are expected to reach 718,000 by 2026. This growth is driven by increased automation in manufacturing sectors worldwide and the need for efficient, reliable production technologies.

Features, Specs & Pricing

– 3DEXPERIENCE Platform: Offers comprehensive solutions for design, simulation, and collaboration across industries.

– KUKA Robotics: Renowned for high precision and flexibility, suitable for various applications from heavy industrial tasks to subtle assembly processes.

Pricing for these technologies can vary significantly based on customization and scale of integration, making it necessary for businesses to consult directly with providers.

Pros & Cons Overview

Pros:

– Enhanced efficiency and reduced time-to-market.

– Improved product quality through virtual simulation.

– Scalability and adaptability to market changes.

Cons:

– High initial investment costs.

– Required workforce upskilling for effective technology adoption.

Security & Sustainability

Security is a top priority when integrating digital and physical systems. Companies should adopt robust cybersecurity measures to protect data and operational integrity. Sustainability is also a driving factor, with the collaboration enabling eco-friendly production practices through optimized resource utilization.

Insights & Predictions

As digital transformation continues to evolve, industries that embrace these innovations will likely see significant advancements in operational efficiency and product innovation. The fusion of leading-edge robotics and design technologies will redefine manufacturing landscapes across the globe.

Actionable Recommendations

– Invest in workforce training to adapt to new technologies quickly.

– Explore partnerships with technology providers to leverage the latest advancements.

– Continuously evaluate and update cybersecurity protocols to safeguard the integrated digital-manufacturing ecosystem.

For more details about Dassault Systèmes and KUKA, visit their official websites: Dassault Systèmes and KUKA.