Ablation-Based Laser Microfabrication Industry Report 2025: Market Dynamics, Technology Innovations, and Strategic Forecasts to 2030

- Executive Summary & Market Overview

- Key Technology Trends in Ablation-Based Laser Microfabrication

- Market Size, Segmentation, and Growth Forecasts (2025–2030)

- Competitive Landscape and Leading Players

- Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Emerging Applications and End-User Insights

- Challenges, Risks, and Market Entry Barriers

- Opportunities and Strategic Recommendations

- Future Outlook: Disruptive Innovations and Market Evolution

- Sources & References

Executive Summary & Market Overview

Ablation-based laser microfabrication is a precision manufacturing technique that utilizes focused laser energy to selectively remove material from a substrate at the microscale. This process enables the creation of intricate patterns, microchannels, and features in a wide range of materials, including metals, polymers, ceramics, and semiconductors. The technology is pivotal in industries such as electronics, medical devices, automotive, and photonics, where miniaturization and high-precision structuring are critical.

The global market for ablation-based laser microfabrication is experiencing robust growth, driven by increasing demand for miniaturized components and the ongoing trend toward advanced manufacturing. According to a 2023 report by MarketsandMarkets, the laser processing market—including microfabrication—was valued at over USD 20 billion in 2023 and is projected to grow at a CAGR of 8–10% through 2028. The ablation segment, in particular, is benefiting from advancements in ultrafast and femtosecond laser technologies, which offer superior precision and minimal thermal damage compared to traditional methods.

Key growth drivers include the proliferation of consumer electronics, where laser ablation is used for drilling microvias in printed circuit boards and fabricating microelectromechanical systems (MEMS). The medical device sector is another major contributor, leveraging laser microfabrication for stent manufacturing, microfluidic device prototyping, and surface texturing of implants to enhance biocompatibility. Additionally, the automotive and aerospace industries are adopting laser ablation for lightweighting components and producing high-performance sensors.

Geographically, Asia-Pacific dominates the market, led by manufacturing powerhouses such as China, Japan, and South Korea. This region accounts for over 40% of global demand, fueled by strong electronics and semiconductor industries (Grand View Research). North America and Europe follow, with significant investments in R&D and the presence of leading laser system manufacturers such as TRUMPF and Coherent.

Looking ahead to 2025, the ablation-based laser microfabrication market is poised for continued expansion, underpinned by technological innovations, increasing adoption in emerging applications, and the push for higher throughput and automation. Challenges remain, including high capital costs and the need for skilled operators, but ongoing advancements in laser sources and process control are expected to mitigate these barriers and further broaden the technology’s industrial footprint.

Key Technology Trends in Ablation-Based Laser Microfabrication

Ablation-based laser microfabrication is witnessing rapid technological evolution as industries demand higher precision, throughput, and material versatility. In 2025, several key technology trends are shaping the landscape of this sector, driven by advancements in laser sources, beam delivery systems, process monitoring, and automation.

- Ultrashort Pulse Lasers: The adoption of femtosecond and picosecond lasers is accelerating, enabling minimal heat-affected zones and superior edge quality. These ultrashort pulse lasers are particularly valuable for processing sensitive materials in electronics, medical devices, and microfluidics. According to Laserfair, the global market for ultrafast lasers is projected to grow at a CAGR of over 10% through 2025, reflecting their increasing integration into microfabrication lines.

- Beam Shaping and Adaptive Optics: Advanced beam shaping technologies, including spatial light modulators and diffractive optical elements, are enabling precise control over ablation profiles. This allows for complex patterning and improved feature resolution, which is critical for applications such as semiconductor wafer dicing and microvia drilling. Companies like TRUMPF and Coherent are investing in adaptive optics to enhance process flexibility and yield.

- Real-Time Process Monitoring: Integration of in-situ monitoring systems, such as optical coherence tomography and machine vision, is becoming standard. These systems provide immediate feedback on ablation quality and depth, reducing defects and enabling closed-loop process control. Novanta and Keyence are leading providers of such monitoring solutions, which are increasingly demanded in high-reliability sectors.

- Automation and Digitalization: The push towards Industry 4.0 is driving the adoption of fully automated laser microfabrication cells, equipped with robotics, AI-driven process optimization, and digital twins. This trend is particularly pronounced in the medical device and electronics industries, where high-volume, high-precision manufacturing is essential. Siemens and Bosch are at the forefront of integrating digital manufacturing solutions with laser ablation systems.

- Green and UV Laser Sources: There is a growing shift towards green (532 nm) and UV (355 nm) lasers for ablation, as these wavelengths offer superior absorption in a wider range of materials, including polymers and transparent substrates. This trend is expanding the application scope of laser microfabrication in emerging fields such as flexible electronics and bioengineering, as noted by MarketsandMarkets.

Collectively, these technology trends are enabling ablation-based laser microfabrication to address increasingly complex manufacturing challenges, supporting innovation across multiple high-tech industries in 2025.

Market Size, Segmentation, and Growth Forecasts (2025–2030)

The global ablation-based laser microfabrication market is poised for robust growth between 2025 and 2030, driven by increasing demand for precision manufacturing in sectors such as electronics, medical devices, and automotive. In 2025, the market size is estimated to reach approximately USD 1.2 billion, with a projected compound annual growth rate (CAGR) of 8.5% through 2030, potentially surpassing USD 1.8 billion by the end of the forecast period. This growth is underpinned by the expanding adoption of laser ablation techniques for micro-drilling, cutting, and surface structuring of advanced materials, including polymers, ceramics, and metals.

Segmentation of the ablation-based laser microfabrication market is typically based on technology type, application, end-user industry, and geography:

- By Technology: The market is segmented into ultrafast (femtosecond and picosecond) lasers, excimer lasers, and CO2 lasers. Ultrafast lasers are expected to witness the highest growth rate due to their superior precision and minimal thermal damage, making them ideal for microelectronics and medical device fabrication.

- By Application: Key applications include micro-drilling, micro-cutting, surface texturing, and thin-film patterning. Micro-drilling and micro-cutting collectively account for over 60% of the market share in 2025, reflecting their critical role in semiconductor and printed circuit board (PCB) manufacturing.

- By End-User Industry: The electronics sector remains the largest end-user, followed by medical devices and automotive. The medical device segment is projected to grow at a CAGR above 9% due to rising demand for minimally invasive surgical tools and implantable devices requiring high-precision features.

- By Geography: Asia-Pacific dominates the market, accounting for more than 45% of global revenue in 2025, led by manufacturing hubs in China, Japan, and South Korea. North America and Europe follow, driven by technological innovation and strong demand from the medical and automotive sectors.

Growth drivers include ongoing miniaturization trends in electronics, increasing complexity of medical devices, and the need for high-throughput, non-contact fabrication methods. However, high capital costs and technical challenges in process optimization may temper growth in certain regions. Leading market players such as TRUMPF Group, Coherent Corp., and IPG Photonics Corporation are investing in R&D to enhance system capabilities and address emerging application needs.

Competitive Landscape and Leading Players

The competitive landscape of the ablation-based laser microfabrication market in 2025 is characterized by a mix of established global players and innovative niche companies, each leveraging advancements in ultrafast laser technology, precision optics, and automation. The market is highly dynamic, driven by increasing demand from sectors such as microelectronics, medical device manufacturing, and photonics, where the need for high-precision, non-contact material processing is paramount.

Key industry leaders include TRUMPF Group, Coherent Corp., and IPG Photonics Corporation. These companies maintain their competitive edge through continuous R&D investment, broad product portfolios, and global service networks. For instance, TRUMPF Group has expanded its ultrashort pulse laser offerings, targeting applications in semiconductor wafer dicing and OLED display fabrication. Coherent Corp. has focused on integrating advanced beam delivery systems and process monitoring, enhancing throughput and quality for micro-drilling and structuring tasks.

Emerging players such as LPKF Laser & Electronics AG and Amplitude Laser are gaining traction by specializing in niche applications like PCB prototyping and femtosecond laser micromachining. These companies often collaborate with research institutions to accelerate innovation and address evolving customer requirements in miniaturization and material diversity.

The market is also witnessing increased activity from Asian manufacturers, notably Han’s Laser Technology Industry Group Co., Ltd. and Maxphotonics Co., Ltd., who are expanding their international presence and offering cost-competitive solutions. Their growth is supported by robust domestic demand in consumer electronics and automotive sectors, as well as strategic partnerships with global OEMs.

Competitive differentiation in 2025 is increasingly based on software integration, process automation, and the ability to handle advanced materials such as ceramics, polymers, and compound semiconductors. Companies are investing in AI-driven process control and real-time quality monitoring to reduce cycle times and improve yield, responding to the stringent requirements of next-generation microfabrication.

Overall, the ablation-based laser microfabrication market remains fragmented but is consolidating as leading players pursue mergers, acquisitions, and technology partnerships to expand their capabilities and global reach, as noted in recent industry analyses by MarketsandMarkets and Global Market Insights.

Regional Market Analysis: North America, Europe, Asia-Pacific, and Rest of World

The ablation-based laser microfabrication market demonstrates distinct regional dynamics across North America, Europe, Asia-Pacific, and the Rest of the World (RoW), shaped by industrial maturity, R&D investment, and end-user demand.

North America remains a leading region, driven by robust semiconductor, medical device, and aerospace sectors. The United States, in particular, benefits from significant investments in advanced manufacturing and microelectronics, with companies such as GE and Intel integrating laser ablation for precision component fabrication. The presence of top research institutions and government funding for innovation further accelerates technology adoption. According to Grand View Research, North America accounted for over 30% of the global market share in 2024, with continued growth expected as demand for miniaturized medical devices and microfluidic chips rises.

Europe is characterized by a strong focus on high-precision manufacturing, particularly in Germany, Switzerland, and the UK. The region’s automotive and medical technology industries are key adopters, leveraging ablation-based laser microfabrication for intricate stent production and microelectromechanical systems (MEMS). The European Union’s emphasis on Industry 4.0 and sustainability is fostering the integration of laser-based processes for cleaner, more efficient manufacturing. LaserWorld reports that European manufacturers are increasingly investing in ultrafast laser systems to meet stringent quality and environmental standards.

Asia-Pacific is the fastest-growing market, propelled by the electronics and semiconductor boom in China, Japan, South Korea, and Taiwan. The region’s dominance in consumer electronics manufacturing, coupled with government initiatives to localize high-tech production, is fueling demand for advanced microfabrication solutions. Companies like Samsung and TSMC are at the forefront, utilizing laser ablation for wafer dicing and microvia drilling. MarketsandMarkets projects that Asia-Pacific will achieve a CAGR above 10% through 2025, outpacing other regions due to rapid industrialization and expanding R&D infrastructure.

- Rest of World (RoW) includes Latin America, the Middle East, and Africa, where adoption is nascent but growing. Market expansion is primarily driven by increasing investments in medical device manufacturing and electronics assembly, particularly in Brazil and Israel. However, limited access to capital and skilled labor remains a challenge for widespread adoption.

Overall, regional market trends in ablation-based laser microfabrication reflect varying degrees of technological maturity, regulatory environments, and sectoral demand, with Asia-Pacific emerging as the primary growth engine through 2025.

Emerging Applications and End-User Insights

Ablation-based laser microfabrication is witnessing a surge in emerging applications across diverse industries, driven by its precision, minimal thermal impact, and adaptability to a wide range of materials. In 2025, the technology is increasingly being adopted in sectors such as microelectronics, medical device manufacturing, photovoltaics, and advanced packaging, each presenting unique end-user requirements and growth opportunities.

In microelectronics, ablation-based laser microfabrication is enabling the production of high-density interconnects, microvias, and flexible circuits. The demand for miniaturized and complex electronic components, especially for 5G and IoT devices, is accelerating the adoption of ultrafast laser ablation techniques. According to SEMI, the microelectronics sector is investing heavily in laser-based processes to achieve finer feature sizes and higher throughput, with a particular focus on femtosecond and picosecond laser systems.

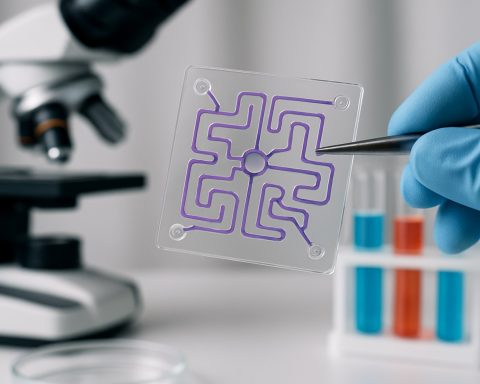

The medical device industry is another prominent end-user, leveraging laser ablation for the fabrication of stents, catheters, and microfluidic devices. The ability to process biocompatible polymers and metals with high precision and without introducing contamination is critical for regulatory compliance and patient safety. MedTech Dive reports that leading medical device manufacturers are integrating laser microfabrication to meet the growing demand for minimally invasive and implantable devices, with a notable shift toward single-use and patient-specific products.

In photovoltaics, ablation-based laser microfabrication is being used for scribing, edge isolation, and patterning of thin-film solar cells. The technology’s non-contact nature and high selectivity are essential for improving cell efficiency and reducing material waste. International Energy Agency (IEA) highlights that as the solar industry moves toward higher-efficiency cell architectures, laser ablation is becoming a standard process step in advanced manufacturing lines.

End-user insights reveal a growing preference for turnkey laser microfabrication systems that offer automation, real-time process monitoring, and integration with digital manufacturing platforms. According to MarketsandMarkets, end-users are prioritizing solutions that reduce cycle times, enhance yield, and support rapid prototyping. The trend toward Industry 4.0 is further driving demand for smart, connected laser systems capable of adaptive process control and predictive maintenance.

Overall, the expanding application landscape and evolving end-user requirements are shaping the future trajectory of ablation-based laser microfabrication, positioning it as a critical enabling technology in next-generation manufacturing.

Challenges, Risks, and Market Entry Barriers

Ablation-based laser microfabrication, while offering high precision and versatility for industries such as electronics, medical devices, and semiconductors, faces several significant challenges, risks, and market entry barriers as of 2025.

- High Capital Investment: The initial cost of advanced laser systems, including ultrafast and femtosecond lasers, remains a substantial barrier for new entrants. These systems require not only expensive hardware but also specialized facilities for safe operation and maintenance. According to Coherent Corp., the total cost of ownership for state-of-the-art laser microfabrication equipment can exceed several million dollars, limiting accessibility for small and medium enterprises.

- Technical Complexity and Skill Shortage: Operating and maintaining ablation-based laser systems demands highly skilled personnel with expertise in optics, materials science, and process engineering. The shortage of such talent, particularly in emerging markets, poses a risk to consistent production quality and process optimization. Laser Institute of America highlights the growing need for specialized training programs to bridge this skills gap.

- Process Control and Repeatability: Achieving consistent results in microfabrication is challenging due to the sensitivity of ablation processes to material properties, laser parameters, and environmental conditions. Variability in substrate composition or minor fluctuations in laser output can lead to defects or reduced yield, impacting profitability and customer trust. TRUMPF Group notes that process monitoring and closed-loop control systems are essential but add further complexity and cost.

- Regulatory and Quality Compliance: Industries such as medical devices and aerospace impose stringent regulatory requirements on microfabricated components. Meeting standards like ISO 13485 or FDA guidelines necessitates rigorous process validation and documentation, increasing the time and resources required for market entry. U.S. Food and Drug Administration (FDA) compliance is particularly demanding for new entrants targeting biomedical applications.

- Intellectual Property (IP) and Competitive Landscape: The field is characterized by dense patent portfolios held by established players, creating risks of infringement and legal disputes. Navigating the IP landscape requires significant legal resources and may deter innovation or entry by smaller firms, as highlighted by IPWatchdog.

These challenges collectively contribute to high market entry barriers, favoring established companies with deep technical expertise, robust financial resources, and strong regulatory experience. Overcoming these obstacles will require strategic partnerships, investment in workforce development, and continuous innovation in process control and compliance.

Opportunities and Strategic Recommendations

The ablation-based laser microfabrication market in 2025 is poised for significant growth, driven by advancements in ultrafast laser technology, increasing demand for miniaturized components, and the expanding application base across electronics, medical devices, and automotive sectors. Key opportunities are emerging from the integration of femtosecond and picosecond lasers, which enable high-precision material removal with minimal thermal damage, making them ideal for fabricating intricate microstructures in sensitive substrates such as polymers, glass, and semiconductors.

One of the most promising opportunities lies in the semiconductor and electronics industries, where the push for smaller, more powerful devices is intensifying. Ablation-based laser microfabrication enables the production of microelectromechanical systems (MEMS), flexible circuits, and advanced packaging solutions with superior accuracy and repeatability. According to SEMI, the global semiconductor market is expected to maintain robust growth, further fueling demand for advanced microfabrication techniques.

In the medical device sector, the trend toward minimally invasive procedures and personalized healthcare is driving the need for micro-scale components such as stents, catheters, and biosensors. Laser ablation offers a contamination-free, contactless process that meets stringent regulatory requirements for biocompatibility and precision. MarketsandMarkets projects the medical device manufacturing market to grow steadily, presenting a lucrative avenue for laser microfabrication providers.

Strategically, companies should invest in R&D to develop multi-wavelength and hybrid laser systems capable of processing a broader range of materials. Collaborations with end-users in high-growth sectors—such as automotive electrification and wearable electronics—can accelerate the adoption of ablation-based solutions. Additionally, integrating real-time process monitoring and AI-driven quality control can enhance throughput and reduce defects, addressing key customer pain points.

- Expand application development teams to work closely with OEMs in target industries.

- Invest in automation and digitalization to streamline production and improve scalability.

- Explore partnerships with material suppliers to co-develop optimized substrates for laser ablation.

- Leverage government incentives for advanced manufacturing and green technologies, as highlighted by European Union and U.S. Department of Energy initiatives.

In summary, the ablation-based laser microfabrication market in 2025 offers robust opportunities for innovation and expansion. Strategic investments in technology, partnerships, and process optimization will be critical for capturing market share and meeting the evolving needs of high-growth industries.

Future Outlook: Disruptive Innovations and Market Evolution

The future outlook for ablation-based laser microfabrication in 2025 is shaped by a convergence of disruptive innovations and evolving market demands. As industries such as electronics, medical devices, and photonics increasingly require miniaturized, high-precision components, laser ablation is positioned to play a pivotal role in next-generation manufacturing processes. The technology’s ability to deliver non-contact, high-resolution material removal is being enhanced by several key trends.

- Ultrafast and Short-Pulse Lasers: The adoption of femtosecond and picosecond lasers is accelerating, enabling ablation with minimal thermal damage and higher feature fidelity. These lasers are particularly valuable for processing sensitive materials in microelectronics and bioengineering. According to MarketsandMarkets, the ultrafast laser market is projected to grow at a CAGR of over 20% through 2025, driven by demand for precision microfabrication.

- Integration with AI and Machine Vision: Real-time process monitoring and adaptive control, powered by artificial intelligence and advanced imaging, are improving yield and throughput. Companies are investing in closed-loop systems that adjust laser parameters dynamically, reducing defects and enabling mass customization. Laser Focus World highlights the growing role of AI in optimizing ablation processes for complex geometries.

- Green and UV Laser Sources: The shift toward shorter wavelengths, such as green (532 nm) and ultraviolet (355 nm) lasers, is expanding the range of processable materials, including transparent polymers and ceramics. This trend is particularly relevant for the display and semiconductor sectors, where fine patterning is critical. Coherent Corp. reports increased adoption of UV lasers for advanced microfabrication applications.

- Emergence of Hybrid Manufacturing: Combining ablation-based laser microfabrication with additive manufacturing and other subtractive techniques is enabling the production of complex, multi-material microstructures. This hybrid approach is expected to unlock new applications in MEMS, microfluidics, and biomedical implants, as noted by IDTechEx.

Looking ahead to 2025, the ablation-based laser microfabrication market is set for robust growth, underpinned by technological breakthroughs and the push for higher precision in miniaturized devices. As these innovations mature, the competitive landscape will favor companies that can integrate advanced laser sources, intelligent automation, and hybrid processing capabilities to meet the evolving needs of high-value industries.

Sources & References

- MarketsandMarkets

- Grand View Research

- TRUMPF

- Coherent

- Laserfair

- Novanta

- Siemens

- Bosch

- IPG Photonics Corporation

- LPKF Laser & Electronics AG

- Amplitude Laser

- Han’s Laser Technology Industry Group Co., Ltd.

- Global Market Insights

- GE

- LaserWorld

- MedTech Dive

- International Energy Agency (IEA)

- IPWatchdog

- European Union

- Laser Focus World

- IDTechEx