Unmasking the Weak Links: A Deep Dive into Fault Injection Testing in Automotive Electronics. Discover how this critical process safeguards vehicles from unseen electronic threats.

- Introduction: The Rising Importance of Fault Injection Testing in Modern Vehicles

- What Is Fault Injection Testing? Methods and Principles Explained

- Why Automotive Electronics Are Vulnerable: Real-World Risks and Scenarios

- Types of Fault Injection: Hardware, Software, and Environmental Approaches

- Key Tools and Technologies Used in Automotive Fault Injection Testing

- Case Studies: Fault Injection Successes and Lessons Learned

- Regulatory Standards and Compliance in Automotive Fault Testing

- Challenges and Limitations: Navigating the Complexities of Testing

- Future Trends: The Evolving Role of Fault Injection in Automotive Cybersecurity

- Conclusion: Building Safer Cars Through Rigorous Fault Injection Testing

- Sources & References

Introduction: The Rising Importance of Fault Injection Testing in Modern Vehicles

The rapid evolution of automotive electronics has transformed modern vehicles into complex, interconnected systems, integrating advanced driver assistance, infotainment, and safety-critical functionalities. As vehicles increasingly rely on electronic control units (ECUs) and sophisticated software, ensuring their reliability and safety has become paramount. Fault injection testing has emerged as a crucial methodology in this context, enabling engineers to systematically introduce faults—such as bit flips, communication errors, or sensor malfunctions—into automotive systems to evaluate their robustness and fault tolerance.

The importance of fault injection testing is underscored by the growing adoption of autonomous driving technologies and the stringent safety standards mandated by regulatory bodies. For instance, compliance with standards like ISO 26262, which governs functional safety in road vehicles, often necessitates rigorous validation of electronic systems under fault conditions (International Organization for Standardization). By simulating real-world failure scenarios, fault injection testing helps identify vulnerabilities that might otherwise remain undetected during conventional testing, thereby reducing the risk of catastrophic failures on the road.

Moreover, the increasing complexity of vehicle networks—such as Controller Area Network (CAN), FlexRay, and Ethernet—demands comprehensive testing strategies to ensure system resilience against both accidental and malicious faults. As the automotive industry moves toward greater connectivity and automation, fault injection testing is becoming an indispensable tool for manufacturers aiming to deliver safe, reliable, and compliant vehicles in a rapidly changing technological landscape (National Highway Traffic Safety Administration).

What Is Fault Injection Testing? Methods and Principles Explained

Fault injection testing is a critical validation technique in automotive electronics, designed to assess the robustness and safety of electronic control units (ECUs) and embedded systems under fault conditions. The core principle involves deliberately introducing faults—such as voltage spikes, signal interruptions, or corrupted data—into hardware or software to observe system behavior and ensure compliance with functional safety standards like ISO 26262 (International Organization for Standardization).

There are several methods of fault injection, each targeting different failure modes. Hardware-based fault injection physically manipulates signals or power lines, simulating real-world electrical disturbances such as short circuits or open connections. Software-based fault injection introduces errors at the code or data level, such as memory corruption or forced exceptions, to test the system’s error handling and recovery mechanisms. Simulation-based fault injection uses virtual models to inject faults during early development stages, enabling rapid iteration and analysis without risking physical hardware (National Highway Traffic Safety Administration).

The principles guiding fault injection testing emphasize repeatability, traceability, and coverage. Tests must be systematically planned to cover critical safety paths and failure scenarios, ensuring that the system can detect, isolate, and mitigate faults as required by automotive safety standards. Effective fault injection not only uncovers latent defects but also validates diagnostic functions and fail-safe strategies, ultimately contributing to the reliability and safety of modern vehicles (SAE International).

Why Automotive Electronics Are Vulnerable: Real-World Risks and Scenarios

Automotive electronics are increasingly complex, integrating advanced driver-assistance systems (ADAS), infotainment, and connectivity features. This complexity, combined with the critical safety roles these systems play, makes them particularly vulnerable to faults—both accidental and malicious. Real-world risks stem from a variety of sources, including electromagnetic interference, component aging, software bugs, and deliberate cyberattacks. For example, electromagnetic disturbances from nearby high-voltage lines or faulty alternators can induce transient faults in electronic control units (ECUs), potentially leading to erratic vehicle behavior or system failures. Similarly, environmental factors such as extreme temperatures or moisture can degrade sensor accuracy or cause intermittent hardware malfunctions.

The growing connectivity of vehicles also introduces new attack surfaces. Remote attackers can exploit vulnerabilities in wireless interfaces, such as Bluetooth or cellular connections, to inject faults or manipulate data streams. Notably, researchers have demonstrated the ability to remotely disable brakes or manipulate steering through software vulnerabilities in connected vehicles, highlighting the real-world consequences of insufficiently tested automotive electronics (National Highway Traffic Safety Administration). Additionally, supply chain risks—such as counterfeit or substandard electronic components—can introduce latent faults that only manifest under specific conditions, making detection and mitigation challenging.

These scenarios underscore the necessity of robust fault injection testing. By systematically introducing faults under controlled conditions, engineers can identify vulnerabilities, assess system resilience, and implement safeguards before vehicles reach consumers. This proactive approach is essential for ensuring both functional safety and cybersecurity in modern automotive electronics (International Organization for Standardization).

Types of Fault Injection: Hardware, Software, and Environmental Approaches

Fault injection testing in automotive electronics employs various approaches to simulate faults and assess system robustness. The three primary types are hardware, software, and environmental fault injection, each targeting different failure modes and system layers.

Hardware fault injection involves introducing physical disturbances directly into the electronic components or circuits. Techniques include shorting pins, inducing voltage spikes, or disconnecting sensors to mimic real-world hardware failures such as broken wires or component degradation. This method is particularly valuable for evaluating the resilience of safety-critical systems like Electronic Control Units (ECUs) and powertrain controllers, as it closely replicates actual hardware faults encountered in vehicles (National Highway Traffic Safety Administration).

Software fault injection targets the embedded code running on automotive systems. By deliberately introducing errors—such as corrupting memory, altering variable values, or simulating timing violations—engineers can observe how the software responds to unexpected conditions. This approach is essential for validating error-handling routines, fail-safe mechanisms, and the overall robustness of automotive software architectures (International Organization for Standardization).

Environmental fault injection simulates external factors that can impact electronic systems, such as electromagnetic interference (EMI), temperature extremes, humidity, or vibration. These tests help ensure that automotive electronics maintain functionality and safety under harsh operating conditions, as required by industry standards like ISO 26262 (United Nations Economic Commission for Europe).

By combining these fault injection methods, automotive manufacturers can comprehensively evaluate system dependability, identify vulnerabilities, and ensure compliance with stringent safety regulations.

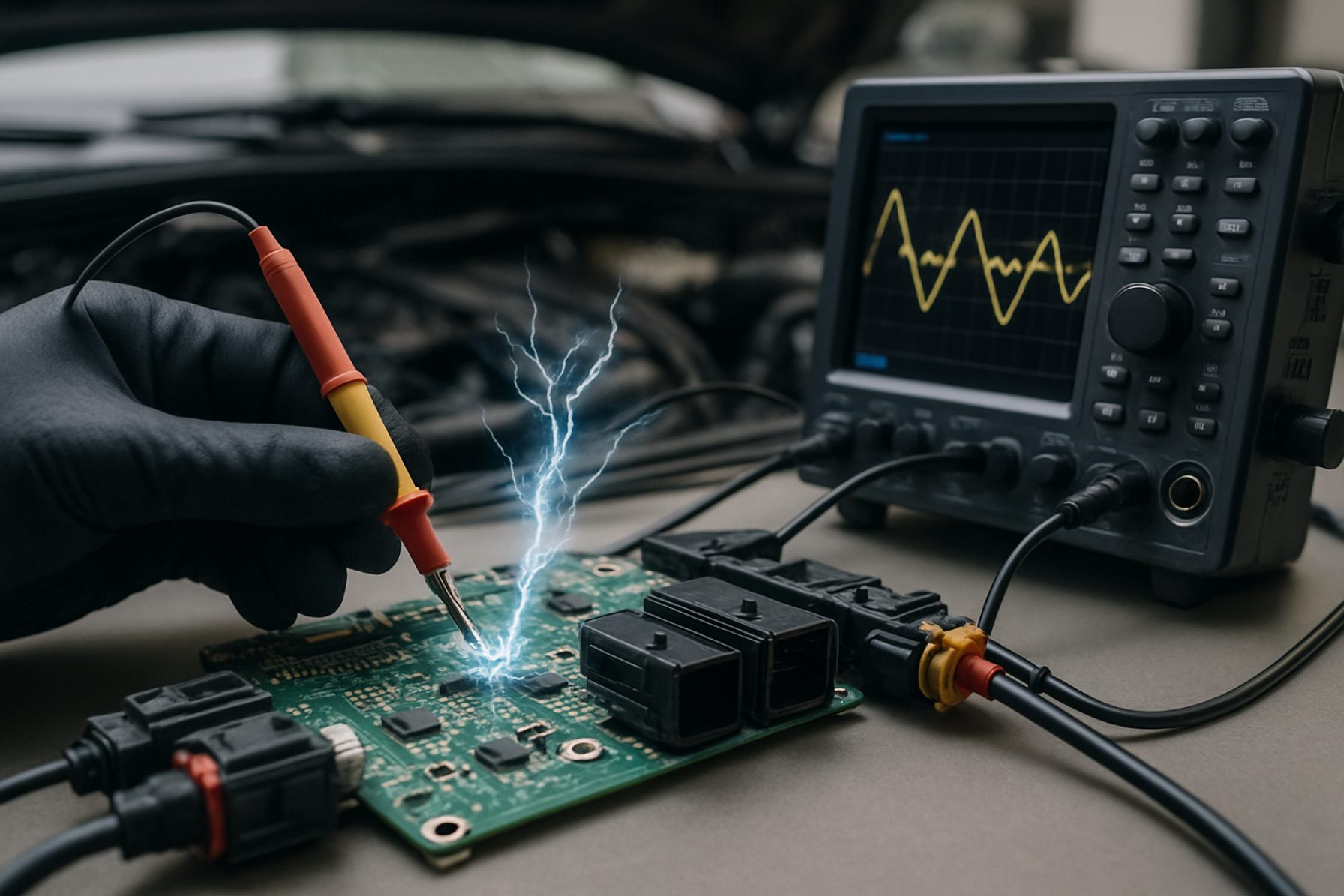

Key Tools and Technologies Used in Automotive Fault Injection Testing

Fault injection testing in automotive electronics relies on a suite of specialized tools and technologies designed to simulate faults and assess system robustness. Hardware-in-the-loop (HIL) simulators are foundational, enabling real-time interaction between electronic control units (ECUs) and simulated vehicle environments. These platforms, such as those provided by dSPACE and National Instruments, allow engineers to inject faults like voltage spikes, signal interruptions, or sensor failures without endangering actual vehicles.

Another critical technology is fault injection software, which can manipulate communication protocols (e.g., CAN, LIN, FlexRay, Ethernet) to introduce errors such as message corruption, delays, or loss. Tools like Vector CANoe and ETAS Fault Injection Units provide comprehensive environments for simulating and analyzing communication faults at both the hardware and software levels.

For physical layer testing, programmable power supplies and signal generators are used to create abnormal voltage, current, or electromagnetic conditions. These devices, often integrated with automated test benches, help evaluate the resilience of ECUs to real-world electrical disturbances. Additionally, advanced monitoring and logging tools capture system responses, enabling detailed post-test analysis.

Emerging technologies, such as AI-driven test automation and cloud-based simulation platforms, are further enhancing the efficiency and coverage of fault injection campaigns. As automotive systems grow more complex, the integration of these advanced tools is essential for ensuring safety and compliance with standards like ISO 26262, as highlighted by International Organization for Standardization.

Case Studies: Fault Injection Successes and Lessons Learned

Case studies in fault injection testing within automotive electronics provide valuable insights into both the successes achieved and the lessons learned from real-world applications. For instance, a leading automotive manufacturer implemented fault injection testing on their electronic control units (ECUs) to assess the robustness of their safety-critical braking systems. By systematically introducing faults such as voltage spikes and communication errors, the team identified a previously undetected vulnerability in the CAN bus communication protocol. This discovery led to a firmware update that significantly improved system resilience, ultimately preventing potential field failures and costly recalls (Bosch Mobility).

Another notable case involved the use of software-based fault injection to validate the fail-operational behavior of advanced driver-assistance systems (ADAS). Here, engineers simulated sensor failures and data corruption scenarios, ensuring that the system could maintain safe operation or transition to a safe state. The process not only confirmed compliance with ISO 26262 requirements but also highlighted the importance of early integration of fault injection in the development lifecycle (International Organization for Standardization).

Lessons learned from these cases emphasize the necessity of a comprehensive fault model, collaboration between hardware and software teams, and the integration of automated fault injection tools. Moreover, they demonstrate that early and continuous fault injection testing can uncover latent defects, reduce development costs, and enhance overall vehicle safety and reliability (National Highway Traffic Safety Administration).

Regulatory Standards and Compliance in Automotive Fault Testing

Regulatory standards and compliance play a pivotal role in shaping fault injection testing practices within automotive electronics. As vehicles become increasingly reliant on complex electronic control units (ECUs) and software-driven functionalities, ensuring their resilience against faults is not only a technical necessity but also a regulatory mandate. Key international standards, such as ISO 26262 for functional safety of road vehicles, explicitly require rigorous fault injection testing to validate the safety mechanisms of automotive systems. This standard outlines processes for identifying potential hazards, implementing safety measures, and verifying their effectiveness through systematic fault injection and analysis.

Additionally, the United Nations Economic Commission for Europe (UNECE) WP.29 regulations, particularly those concerning cybersecurity (UN R155) and software updates (UN R156), emphasize the need for robust testing methodologies, including fault injection, to ensure both safety and security of automotive electronics. Compliance with these regulations is mandatory for market access in many regions, driving manufacturers to integrate fault injection testing into their development and validation workflows.

Automotive OEMs and suppliers must also consider regional standards, such as the SAE J3061 Cybersecurity Guidebook, which further reinforces the importance of fault-based testing for both safety and security assurance. Non-compliance can result in legal liabilities, product recalls, and loss of consumer trust. As regulatory landscapes evolve, continuous alignment with these standards is essential, making fault injection testing a cornerstone of both technical excellence and regulatory compliance in the automotive industry.

Challenges and Limitations: Navigating the Complexities of Testing

Fault injection testing in automotive electronics is a critical methodology for validating the robustness and safety of electronic control units (ECUs) and embedded systems. However, this approach faces several significant challenges and limitations that must be carefully navigated to ensure meaningful results. One major challenge is the increasing complexity and integration of automotive systems, which often involve multiple interconnected ECUs, sensors, and actuators. This complexity makes it difficult to comprehensively inject faults and predict their propagation throughout the system, potentially leading to incomplete coverage of failure modes National Highway Traffic Safety Administration.

Another limitation is the realism of injected faults. Simulated faults may not always accurately represent real-world failure mechanisms, such as those caused by aging, environmental stress, or manufacturing defects. This can result in a gap between test outcomes and actual field behavior. Additionally, the need for specialized hardware and software tools to perform fault injection—such as hardware-in-the-loop (HIL) simulators—can increase both the cost and complexity of the testing process International Organization for Standardization.

Safety is also a concern, as injecting faults into safety-critical systems can pose risks to test personnel and equipment. Strict protocols and isolation measures are required to prevent unintended consequences. Furthermore, regulatory requirements, such as those outlined in ISO 26262, demand rigorous documentation and traceability, adding to the administrative burden of fault injection campaigns United Nations Economic Commission for Europe. These challenges underscore the need for a balanced approach that combines fault injection with complementary testing methods to achieve comprehensive safety validation in automotive electronics.

Future Trends: The Evolving Role of Fault Injection in Automotive Cybersecurity

As automotive systems become increasingly connected and software-driven, the role of fault injection testing is rapidly evolving to address emerging cybersecurity threats. Traditionally, fault injection focused on validating the robustness of electronic control units (ECUs) against random hardware faults or software bugs. However, with the proliferation of advanced driver-assistance systems (ADAS), over-the-air updates, and vehicle-to-everything (V2X) communications, the attack surface for cyber threats has expanded significantly. Modern fault injection techniques are now being adapted to simulate not only accidental faults but also deliberate, malicious attacks that could compromise vehicle safety and data integrity.

Future trends indicate a convergence of fault injection and penetration testing, where security researchers use sophisticated tools to inject faults at the hardware, firmware, and software levels, mimicking real-world cyberattacks. This includes voltage and clock glitching, electromagnetic interference, and protocol fuzzing to expose vulnerabilities in cryptographic modules, secure boot processes, and communication interfaces. The integration of artificial intelligence and machine learning is also anticipated, enabling automated identification of weak points and adaptive test scenarios that evolve with the threat landscape.

Regulatory bodies and industry alliances are recognizing the importance of these advanced testing methodologies. Standards such as ISO/SAE 21434 and UNECE WP.29 now emphasize cybersecurity validation, including the use of fault injection to demonstrate resilience against both accidental and intentional disruptions (International Organization for Standardization, United Nations Economic Commission for Europe). As vehicles become more autonomous and interconnected, fault injection testing will remain a cornerstone of proactive cybersecurity assurance in automotive electronics.

Conclusion: Building Safer Cars Through Rigorous Fault Injection Testing

Rigorous fault injection testing is a cornerstone in the pursuit of safer automotive electronics. By systematically introducing faults—whether at the hardware, software, or communication level—engineers can proactively identify vulnerabilities and failure modes that might otherwise remain undetected until real-world incidents occur. This proactive approach is especially critical as vehicles become increasingly reliant on complex electronic control units (ECUs) and advanced driver-assistance systems (ADAS), where undetected faults can have severe safety implications.

The adoption of fault injection testing aligns with international safety standards such as ISO 26262, which mandates rigorous validation of safety-critical automotive systems. Through comprehensive fault injection campaigns, manufacturers can ensure that their systems not only detect and handle faults gracefully but also meet regulatory requirements and consumer expectations for reliability. Moreover, the insights gained from these tests inform design improvements, leading to more robust architectures and effective fault-tolerant mechanisms.

Ultimately, integrating fault injection testing throughout the development lifecycle fosters a culture of safety and continuous improvement. As the automotive industry moves toward greater automation and connectivity, the importance of such testing will only grow. By embracing these rigorous methodologies, manufacturers can build vehicles that are not only technologically advanced but also fundamentally safer for drivers, passengers, and all road users.

Sources & References

- International Organization for Standardization

- dSPACE

- National Instruments

- ETAS Fault Injection Units

- Bosch Mobility