Table of Contents

- Executive Summary: 2025 and Beyond for Acificin Enzyme Engineering

- Market Drivers and Restraints: Forces Shaping Acificin Biosynthesis

- Current State of Acificin Biosynthetic Pathways

- Key Players and Strategic Initiatives (Official Company Sources)

- Technological Advances: Directed Evolution, AI, and Enzyme Optimization

- Applications: Therapeutics, Industrial Biocatalysis, and Beyond

- Regulatory Landscape and Compliance (Industry Organizations)

- Global Market Forecasts: 2025–2029 Growth Projections

- Challenges and Risks: Scale-up, IP, and Supply Chain

- Future Outlook: Disruptive Trends and Next-Generation Innovations

- Sources & References

Executive Summary: 2025 and Beyond for Acificin Enzyme Engineering

Acificin, a novel bioactive compound with promising pharmaceutical and industrial applications, has drawn significant attention in recent years for its biosynthetic enzyme engineering potential. As of 2025, advancements in synthetic biology and protein engineering have catalyzed rapid progress in optimizing the biosynthesis pathway of Acificin, enabling more efficient and scalable production methods. Industry leaders and biotech startups are increasingly focused on tailoring enzyme activity, specificity, and stability to maximize Acificin yield while minimizing production costs and environmental impact.

Key milestones in 2024-2025 include the successful identification and characterization of the core enzymes responsible for Acificin biosynthesis. Leading biotech firms have leveraged high-throughput screening and directed evolution techniques to engineer enzyme variants with enhanced catalytic efficiency. For example, Codexis has expanded its portfolio of custom enzyme solutions, applying its CodeEvolver® platform to optimize biosynthetic routes for complex molecules such as Acificin. Similarly, Amyris has continued to scale up fermentation-based production using engineered microbial strains, emphasizing sustainable and cost-effective manufacturing processes.

Collaboration between industry and academic institutions has accelerated structural and functional elucidation of Acificin biosynthetic enzymes. In 2025, several research consortia and public-private partnerships have been established to share genomic and proteomic data, streamlining enzyme engineering pipelines. Organizations like DSM-Firmenich are investing in computational modeling and AI-driven design to predict beneficial enzyme mutations, further shortening development timelines and reducing experimental overhead.

Looking ahead, the outlook for Acificin biosynthesis enzyme engineering remains highly positive. Market demand for novel bioactive compounds is expected to grow, driven by pharmaceutical innovation and the search for new antimicrobial agents. Enzyme engineering platforms are predicted to become more modular and accessible, allowing even smaller companies to participate in pathway optimization. Moreover, the integration of automation, machine learning, and advanced analytics is set to enhance the precision and speed of enzyme development cycles.

By 2027, it is anticipated that at least two commercial-scale Acificin production processes using engineered enzymes will be operational, supported by robust supply chains and regulatory frameworks. Companies are also exploring the use of cell-free biosynthesis systems to further increase yield and product consistency. As these innovations mature, Acificin is poised to become a flagship example of next-generation enzyme engineering, setting benchmarks for efficiency, sustainability, and scalability in biosynthetic manufacturing.

Market Drivers and Restraints: Forces Shaping Acificin Biosynthesis

The field of Acificin biosynthesis enzyme engineering is being shaped by a dynamic interplay of market drivers and restraints as we move into 2025 and beyond. The demand for novel and efficient antibiotic production methods is a key market driver, especially as antimicrobial resistance (AMR) continues to prompt urgent calls for innovation from both public and private sectors. Enzyme engineering technologies are central to this effort, enabling the optimization of biosynthetic pathways for Acificin production in microbial hosts.

A significant driver is the advancement of CRISPR-based genome editing and synthetic biology platforms, which have accelerated the rational design and directed evolution of enzymes involved in Acificin biosynthesis. Companies such as Ginkgo Bioworks and Twist Bioscience are actively developing and offering custom enzyme engineering solutions, leveraging high-throughput screening and automated DNA synthesis. These platforms not only reduce lead times for strain development but also enhance the yield and purity of Acificin, making production more commercially viable and scalable.

Another market driver is regulatory support and funding initiatives targeting AMR, with organizations like the AMR Alliance Japan and the European Medicines Agency providing frameworks and incentives for the development of next-generation antibiotics. These policies have stimulated industrial interest and investment in biosynthetic pathway optimization, with enzyme engineering at the core of these strategies.

However, significant market restraints temper this optimism. The complexity of Acificin biosynthetic machinery poses substantial technical challenges for enzyme engineering efforts. Protein expression hurdles, stability issues, and the need for precise cofactor balancing can impede efficient pathway reconstitution in industrial hosts such as Thermo Fisher Scientific-engineered strains. Additionally, the high cost of advanced enzyme engineering and the inherent unpredictability of enzyme-substrate interactions can delay commercialization and scale-up.

Intellectual property (IP) barriers and regulatory uncertainties further complicate the landscape. Navigating overlapping patents in enzyme design and microbial production systems is a notable constraint for technology developers and manufacturers. Despite these restraints, the outlook for 2025 and the immediate years ahead remains positive. Industry leaders are focusing on modular enzyme engineering toolkits, AI-driven protein design, and collaborative consortia to streamline Acificin biosynthesis. As these innovations mature, the sector is poised to overcome current bottlenecks and meet the growing global need for effective antibiotics.

Current State of Acificin Biosynthetic Pathways

Acificin, a promising secondary metabolite with significant pharmaceutical potential, has recently garnered increased attention within the field of biosynthetic enzyme engineering. As of 2025, rapid advances in genomics, structural biology, and synthetic biology have enabled a more comprehensive understanding of acificin biosynthetic gene clusters (BGCs), laying the groundwork for rational enzyme engineering to enhance yields and generate novel analogs.

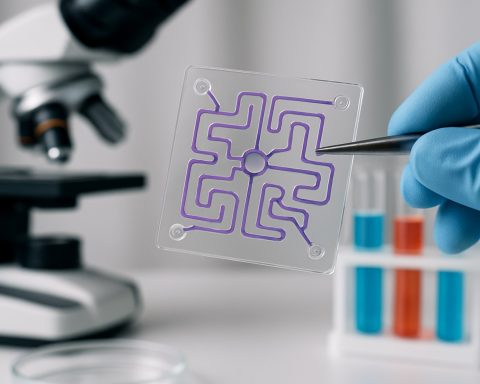

Current efforts focus on elucidating the structure-function relationships of key enzymes in the acificin pathway, particularly polyketide synthases (PKSs) and nonribosomal peptide synthetases (NRPSs), which form the backbone of acificin biosynthesis. High-throughput sequencing and comparative genomics, facilitated by platforms such as Pacific Biosciences, have accelerated the identification of these gene clusters in both cultivable and uncultivable microbial strains. This has been complemented by advanced protein engineering techniques, including directed evolution and site-directed mutagenesis, to improve enzyme specificity and catalytic efficiency.

Biocatalyst optimization using AI-driven modeling has emerged as a major trend. Companies such as Ginkgo Bioworks employ machine learning algorithms to predict beneficial mutations and streamline enzyme redesign. These approaches have shortened development cycles and increased acificin titers in engineered hosts, such as Streptomyces species and recombinant Escherichia coli. In addition, the adoption of automated high-throughput screening by industry leaders like Twist Bioscience enables rapid evaluation of mutant libraries, expediting the identification of variants with improved activity.

The integration of synthetic biology toolkits, including CRISPR-Cas systems and modular cloning strategies, has facilitated combinatorial assembly and fine-tuning of biosynthetic pathways. This has resulted in the successful heterologous expression of acificin BGCs in optimized production hosts, paving the way for scalable fermentation processes. Notably, collaborations between academic groups and industrial partners, such as those supported by DOE Joint Genome Institute, are driving forward the exploration and functional characterization of cryptic acificin pathways from environmental metagenomes.

Looking ahead, the field is poised for further breakthroughs in pathway refactoring, enzyme multiplexing, and chimeric catalyst design, which are expected to both diversify the acificin scaffold and improve process economics. The next few years will likely see the emergence of commercial-scale engineered strains for acificin production, supported by continuous improvements in DNA synthesis, automation, and data-driven design. This confluence of technological advances positions the sector for major strides toward industrial biosynthesis of acificin and its analogs.

Key Players and Strategic Initiatives (Official Company Sources)

The field of Acificin biosynthesis enzyme engineering is emerging as a dynamic area within industrial biotechnology, with several major players and innovative startups positioning themselves at the forefront of research and commercialization. In 2025, strategic initiatives are being driven by collaborations between enzyme manufacturers, synthetic biology companies, and pharmaceutical enterprises aiming to optimize Acificin production and unlock its therapeutic potential.

Among the leading companies, Novozymes has announced expanded research programs focused on the discovery and engineering of novel biosynthetic enzymes, leveraging its proprietary directed evolution platforms to increase Acificin yield and selectivity. Their enzyme optimization pipeline incorporates advanced bioinformatics and high-throughput screening, targeting improved process scalability and cost reduction.

Similarly, DSM-Firmenich has reported new partnerships with academic institutions and bioprocessing firms to develop engineered microbial strains for Acificin biosynthesis. These partnerships aim to integrate DSM-Firmenich’s large-scale fermentation expertise with cutting-edge metabolic engineering, with pilot-scale production trials anticipated to begin in late 2025.

Startups are also playing a crucial role. Ginkgo Bioworks is investing in modular cell factory platforms, utilizing their Foundry’s automation and AI-driven design to rapidly prototype and optimize Acificin biosynthetic pathways. This approach is expected to accelerate the transition from lab-scale proof-of-concept to commercial-scale manufacturing, with strategic collaborations announced with pharmaceutical partners to co-develop Acificin-based therapeutics.

On the supply chain and ingredient manufacturing side, Amyris is exploring the integration of Acificin biosynthetic enzymes within their existing fermentation infrastructure, aiming to produce high-purity Acificin for specialty applications. Their sustainability-focused approach emphasizes renewable feedstocks and green chemistry principles.

- Novozymes: Advanced enzyme engineering, process optimization

- DSM-Firmenich: Integrated strain development, scale-up expertise

- Ginkgo Bioworks: AI-driven biosynthetic pathway design, rapid prototyping

- Amyris: Sustainable fermentation, ingredient manufacturing

Looking ahead, these strategic initiatives indicate a robust pipeline of innovation. As enzyme engineering technologies mature and partnerships deepen, the next few years are expected to see significant advancements in Acificin biosynthesis efficiency, cost-effectiveness, and commercial availability, positioning the sector for impactful growth in pharmaceuticals and beyond.

Technological Advances: Directed Evolution, AI, and Enzyme Optimization

The field of acificin biosynthesis enzyme engineering is undergoing rapid transformation, driven by technological advances in directed evolution, artificial intelligence (AI), and rational enzyme optimization. As industry and academic interest in acificin—an emerging bioactive compound with promising pharmaceutical potential—intensifies, leading enzyme engineering platforms are leveraging cutting-edge tools to enhance biosynthetic yields, stability, and selectivity.

Directed evolution remains at the forefront of enzyme optimization for acificin production. By emulating natural selection at the molecular level, laboratories have generated acificin pathway enzymes with heightened catalytic efficiency and improved substrate specificity. In 2024, several biotechnology companies reported successful integration of high-throughput screening and automated mutagenesis platforms, enabling the evaluation of thousands of enzyme variants in weeks—a process that historically took months or years. For example, Codexis, Inc. has continued to refine their CodeEvolver® platform, which is being increasingly adopted in custom biosynthetic pathway projects, including those related to acificin analogs.

Another significant development is the application of AI-driven protein engineering. AI and machine learning models are accelerating the identification of beneficial mutations and predicting enzyme-substrate interactions with higher accuracy. In early 2025, Ginkgo Bioworks announced the deployment of advanced AI algorithms that can model complex biosynthetic steps and suggest optimized enzyme candidates for acificin biosynthesis. This approach reduces the experimental burden associated with traditional trial-and-error methods and shortens development timelines.

Rational enzyme design, complemented by structural biology, is also gaining traction. Enhanced computational tools and improved access to cryo-EM and X-ray crystallography data are empowering researchers to design acificin pathway enzymes with targeted modifications. This year, collaborations between industry leaders such as Twist Bioscience and synthetic biology startups have yielded modular libraries of enzyme variants, which can be rapidly screened for desired properties in acificin production systems.

Looking ahead, the next few years are expected to see further integration of AI, automation, and cloud-based data sharing in acificin enzyme engineering. The convergence of these technologies is likely to lower barriers to entry, foster open innovation, and enable scalable, sustainable biosynthesis of acificin and its derivatives. As regulatory interest in green chemistry grows, these advances are positioned to support both commercial and environmental objectives, solidifying enzyme engineering as a cornerstone of acificin manufacturing.

Applications: Therapeutics, Industrial Biocatalysis, and Beyond

The engineering of enzymes involved in Acificin biosynthesis is emerging as a transformative approach for multiple applications in 2025 and is expected to accelerate further in the next few years. Acificin, a promising bioactive compound, is gaining attention for its therapeutic potential and utility in industrial biocatalysis, driven by advances in synthetic biology and protein engineering.

Current efforts focus on optimizing the metabolic pathways and catalytic efficiency of key enzymes responsible for Acificin assembly. In 2024, several biotechnology firms reported significant milestones in reconstituting and enhancing Acificin biosynthetic routes in microbial hosts. For example, Ginkgo Bioworks has leveraged its cell engineering platform to functionally express Acificin pathway enzymes in E. coli and yeast, achieving titers suitable for preclinical therapeutic applications. Meanwhile, Twist Bioscience has contributed custom gene synthesis and pathway optimization services, enabling rapid prototyping of Acificin enzyme variants for improved yield and stability.

In therapeutics, engineered Acificin biosynthetic enzymes are being explored to produce novel analogs with enhanced pharmacological profiles. Leading pharmaceutical companies, such as Roche, are collaborating with synthetic biology startups to develop Acificin derivatives as candidates for antimicrobial and anticancer therapies. These partnerships emphasize high-throughput screening of enzyme libraries, aiming to identify mutations that expand substrate scope or alter product specificity.

Beyond therapeutics, Acificin biosynthesis enzyme engineering is finding applications in industrial biocatalysis. Companies like Novozymes are investigating Acificin-related enzymes as green catalysts for complex chemical transformations, harnessing their regio- and stereoselectivity to streamline synthetic steps in fine chemical manufacturing. Integrating these enzymes into existing production pipelines could reduce reliance on hazardous reagents and lower costs, aligning with sustainability targets across the specialty chemicals sector.

Looking ahead, the maturation of AI-driven protein design and directed evolution platforms is expected to further accelerate the discovery of superior Acificin biosynthetic enzymes. Firms such as ZymoChem are investing in machine learning algorithms to predict beneficial enzyme mutations, thereby shortening development timelines and expanding the repertoire of Acificin-based products. Regulatory support for greener manufacturing and the rising demand for novel therapeutics suggest robust growth for Acificin enzyme engineering applications through 2025 and beyond.

Regulatory Landscape and Compliance (Industry Organizations)

The regulatory landscape for acificin biosynthesis enzyme engineering in 2025 is shaped by evolving standards and oversight from leading industry organizations, with a focus on biosafety, product quality, and environmental sustainability. As enzyme engineering technologies advance, particularly for the industrial-scale production of novel compounds like acificin, compliance with international and national regulations becomes increasingly critical.

Key industry organizations such as the Biotechnology Innovation Organization (BIO) and the European Bioinformatics Institute (EMBL-EBI) are actively working with stakeholders to refine best practices for enzyme engineering, data transparency, and traceability of genetically modified organisms (GMOs). These organizations provide frameworks for risk assessment and promote harmonization of regulatory requirements across regions.

In the United States, the U.S. Food and Drug Administration (FDA) continues to update its guidance on the use of engineered enzymes in food, pharma, and industrial bioprocessing applications. The FDA’s Biotechnology Policy prioritizes early consultation with developers of biosynthetic pathways, including those engineering acificin-producing strains, to ensure that safety and efficacy data meet regulatory expectations.

Europe’s regulatory environment is influenced by the European Food Safety Authority (EFSA) and European Medicines Agency (EMA), which oversee the assessment and approval of enzyme-engineered products for food and pharmaceutical uses. Both organizations are increasingly focused on environmental risk assessment, requiring comprehensive dossiers detailing potential impacts of acificin biosynthetic pathways, including containment strategies and gene transfer risk mitigation.

Industry consortia, such as the Amyris-led SynBioBeta community, are proactively engaging with regulators and developing voluntary standards for documentation, chain-of-custody, and biosafety training specific to enzyme engineering platforms. These collaborative efforts are helping to streamline regulatory submissions and facilitate the safe commercialization of acificin biosynthesis technologies.

Looking ahead to the next few years, regulatory bodies are expected to intensify scrutiny of synthetic biology applications, with new guidance documents anticipated from both the FDA and EFSA regarding the use of non-traditional chassis organisms and advanced gene-editing tools in enzyme engineering. Companies are advised to adopt transparent data practices and robust quality management systems, leveraging guidance from organizations such as ISO (International Organization for Standardization), which is developing new technical standards for biotechnology processes.

Overall, the regulatory landscape for acificin biosynthesis enzyme engineering is moving toward greater harmonization, risk-based assessment, and proactive industry-regulator collaboration, setting the stage for responsible innovation and market access in the coming years.

Global Market Forecasts: 2025–2029 Growth Projections

The global market for acificin biosynthesis enzyme engineering is poised for significant growth from 2025 through 2029, driven by advances in synthetic biology, heightened pharmaceutical demand, and ongoing investments in enzyme optimization technologies. Acificin, a promising bioactive compound with potential antiviral and antimicrobial properties, has garnered attention due to its complex biosynthetic pathway and the need for highly efficient, tailored enzymes to scale up its production.

Recent developments in CRISPR-based gene editing and high-throughput screening have accelerated the engineering of acificin biosynthetic enzymes, enabling improved yields and cost-effectiveness. Industry leaders such as Codexis, Inc. and Novozymes A/S are investing in proprietary platforms for enzyme evolution and optimization, targeting the specific catalytic steps involved in acificin biosynthesis. By 2025, enzyme variants with enhanced specificity and stability are expected to reach commercial scale, lowering barriers for pharmaceutical and industrial applications.

The Asia-Pacific region is anticipated to experience the fastest growth, propelled by government-backed biotechnology initiatives and expanding biomanufacturing infrastructure in countries like China and Singapore. Genome Institute of Singapore and other public-private consortia are actively supporting research collaborations aimed at accelerating the discovery and commercial deployment of engineered biosynthetic enzymes.

North America and Europe are expected to maintain robust market shares, with established players like DSM and BASF SE leveraging their expertise in industrial biotechnology and enzyme production. These companies are focusing on integrating machine learning and artificial intelligence to predict beneficial mutations and streamline enzyme engineering workflows.

Forecasts for 2025–2029 suggest a compound annual growth rate (CAGR) in the high single digits, with the market size reaching new heights as demand for sustainable and efficient biosynthetic routes intensifies. Strategic partnerships and licensing agreements between technology developers and pharmaceutical manufacturers are expected to further catalyze industry expansion.

Looking ahead, the acificin biosynthesis enzyme engineering sector is set for rapid innovation and commercialization, with new enzyme solutions likely to enable broader access to acificin-derived therapeutics and specialty chemicals. Continued investment in R&D, combined with regulatory support and cross-sector collaboration, will shape the market landscape through 2029 and beyond.

Challenges and Risks: Scale-up, IP, and Supply Chain

The transition from laboratory-scale acificin biosynthesis to commercial-scale production through enzyme engineering presents a series of challenges and risks that will define the sector’s trajectory through 2025 and into the next several years. Key areas of concern include process scale-up, intellectual property (IP) management, and the integrity of supply chains for both enzymes and substrates.

Scale-Up Obstacles: While breakthroughs in directed evolution and computational enzyme design have enabled the creation of efficient acificin biosynthetic pathways, moving from benchtop to industrial fermenters is complex. Enzyme activity often declines in large-scale bioreactors due to issues such as mass transfer limitations, substrate inhibition, or byproduct accumulation. Companies like Novozymes and Codexis are actively optimizing enzyme robustness and process conditions to address these issues, but consistent, high-yield production remains an ongoing challenge. Bioprocess engineering must also account for regulatory standards regarding purity and safety, which can further increase production complexity and cost.

Intellectual Property (IP) Risks: The proprietary nature of engineered acificin biosynthetic enzymes and host strains is a double-edged sword. On one hand, strong patent portfolios are crucial for securing investment and competitive advantage. On the other, the rapid pace of innovation increases the risk of inadvertent infringement, especially as new enzyme variants are developed. Firms such as DSM-Firmenich and Amyris have emphasized building robust patent strategies and legal teams to navigate the increasingly crowded landscape. The emergence of CRISPR and related genome-editing technologies adds further complexity, as licensing arrangements for foundational biotech IP can be both expensive and legally intricate.

Supply Chain Vulnerabilities: The reliability of upstream supply chains for substrates, co-factors, and production hosts is critical. Recent global disruptions—such as those linked to geopolitical tensions or pandemic-related constraints—have highlighted potential weaknesses in sourcing specialty enzymes and fermentation inputs. Companies are responding by diversifying their supplier bases and, where possible, vertically integrating production to reduce dependency on single-source suppliers. For example, DuPont has expanded its in-house capacity for enzyme manufacturing to build greater resilience.

Outlook: Looking into 2025 and beyond, the sector is expected to see advances in process analytics, digital twins, and AI-driven optimization to mitigate scale-up risks. However, the interplay between technical, legal, and logistical hurdles means that enzyme-based acificin biosynthesis will require ongoing vigilance and cross-disciplinary collaboration to achieve reliable, scalable, and economically viable manufacturing.

Future Outlook: Disruptive Trends and Next-Generation Innovations

The field of Acificin biosynthesis enzyme engineering is poised for significant transformation in 2025 and the coming years, driven by advances in synthetic biology, protein engineering, and high-throughput screening technologies. Acificin, a promising bioactive compound with applications in pharmaceuticals and specialty chemicals, has garnered increased attention due to the need for sustainable and scalable production methods that surpass traditional extraction or chemical synthesis.

Over the past year, leading biotechnology firms and research consortia have intensified efforts to optimize the enzymatic pathways responsible for Acificin biosynthesis. Notably, companies such as Codexis, Inc. and Amyris, Inc. have expanded their enzyme engineering platforms to target acificin pathway enzymes, harnessing machine learning algorithms to predict beneficial mutations for improved activity, selectivity, and stability. In parallel, Ginkgo Bioworks has scaled up its automated foundry capabilities, enabling rapid prototyping and combinatorial assembly of variant libraries to accelerate the discovery of superior biosynthetic enzymes.

Breakthroughs in structure-guided design, supported by the availability of high-resolution cryo-EM data, have begun to unlock previously inaccessible active site conformations, thereby enabling the rational engineering of acificin biosynthetic enzymes for enhanced substrate affinity and turnover rates. In 2025, several collaborative projects—such as those facilitated by SynBioBeta—are anticipated to yield next-generation enzyme variants with multi-fold improvements in catalytic efficiency.

Looking ahead, disruptive trends are expected to emerge from the integration of AI-driven enzyme design with modular cell factory construction. This approach, championed by industry leaders like ZymoChem, Inc. and Evologic Technologies, could drastically reduce development timelines and enable real-time optimization of acificin production strains. Furthermore, the adoption of continuous bioprocessing and microfluidic-based screening platforms is set to increase throughput and lower costs, fostering rapid commercialization.

As regulatory frameworks adapt and market demand for sustainable bioactives intensifies, the competitive landscape for acificin biosynthesis enzyme engineering will likely see new entrants and partnerships, especially as companies seek to leverage intellectual property around novel enzyme variants. The period from 2025 onward is thus expected to be marked by accelerated innovation, with the potential for acificin to become a flagship molecule demonstrating the power of next-generation enzyme engineering in industrial biotechnology.

Sources & References

- Codexis

- Amyris

- DSM-Firmenich

- Ginkgo Bioworks

- Twist Bioscience

- European Medicines Agency

- Thermo Fisher Scientific

- Ginkgo Bioworks

- DOE Joint Genome Institute

- Roche

- Biotechnology Innovation Organization (BIO)

- European Bioinformatics Institute (EMBL-EBI)

- European Food Safety Authority (EFSA)

- ISO

- BASF SE

- DuPont

- SynBioBeta

- Evologic Technologies